Taulman "645" Natural Nylon 0.45kg 2.85mm

or 4 payments of $11.99 with

Info

Info

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

$10 Flat Rate Shipping - $10.00

Your order will be shipped by the most economical option, with online tracking. Delivery is usually 2-7 business days.

TNT/DHL - Next Day Express Domestic - $10.00

1 day delivery! Please note Business address only. Residential addresses will incur a fee.

Free pick-up from store - FREE

Free pick-up from '781 High St, Reservoir VIC 3073', between 9am and 5pm

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

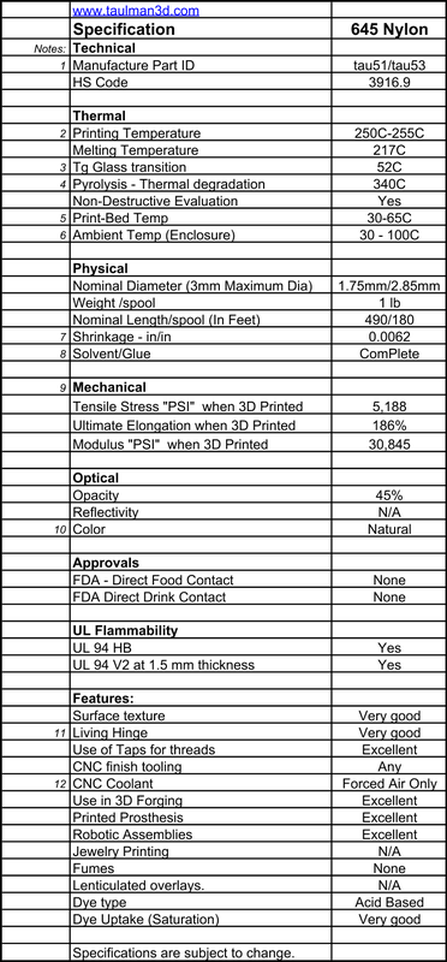

Features of Taulman 645 3D printing material

(T3D-645-NAT-2.85)

| SKU | T3D-645-NAT-2.85 |

| Brand | Taulman3D |

| Shipping Weight | 1.3500kg |

| Shipping Width | 0.210m |

| Shipping Height | 0.080m |

| Shipping Length | 0.220m |

| Shipping Cubic | 0.003696000m3 |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.