800 Pro Large Format SLA Printer

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

$10 Flat Rate Shipping - $10.00

- Delivery in 2-7 Business Days.

- Most Economical Option

- Australia Wide

- Online Tracking Available

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

800 Pro SLA Industrial 3D Printer

Advanced Large Format Solutions from 3D Printer Gear

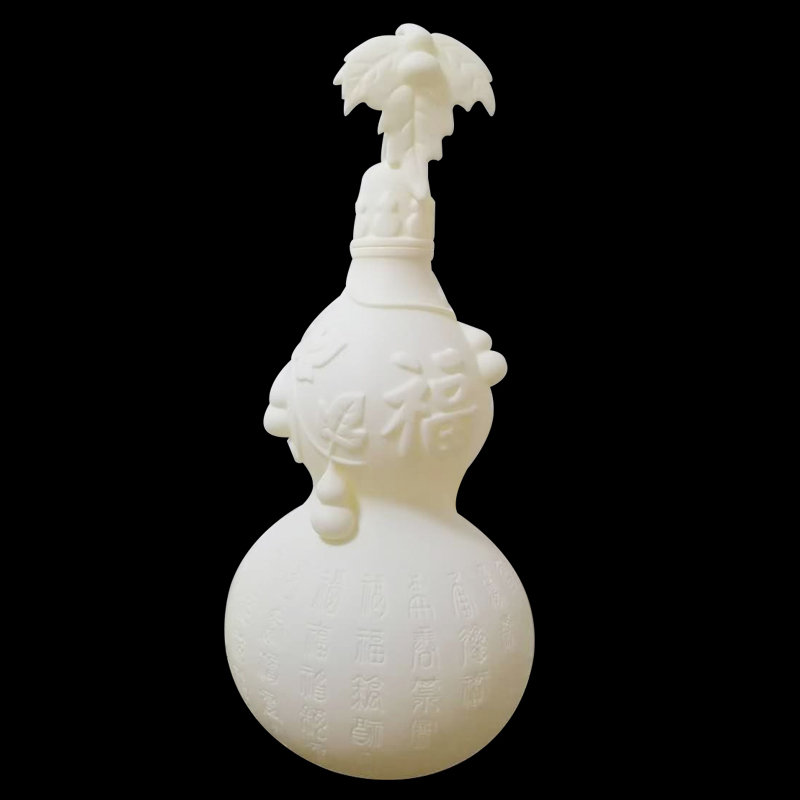

SLA 3D printing, also known as stereolithography, utilizes mature photocuring technology to rapidly produce prototypes directly from CAD models, offering advantages such as speed, intricate detail, and ease of design changes. Its applications span various industries, including manufacturing, product design, engineering, automotive, jewelry, dentistry, education, and model making, making it an ideal choice for creating highly detailed prototypes, molds, and assembly parts with complex structures.

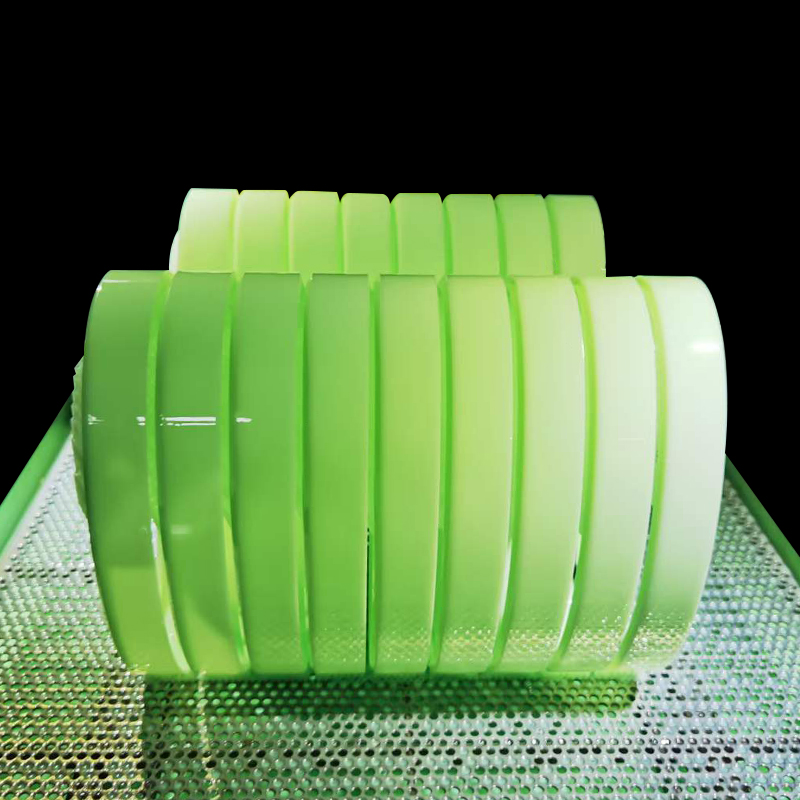

The 800 Pro SLA printer can produce huge parts in extreme detail allowing for the precise reproduction of CAD models rapidly and accurately. The size of the printer bed also allows batch printing of hundreds of smaller parts speeding up production time massively.

Features

- Variable laser spot size and variable power

- Automatic identifying upskin and downskin with differentiated parameters

- Different Parameter database with different layer thickness

- Optowave laser from the US, Scanlab galvanometer from Germany

- Full epoxy granite structure for enhanced recoating and scanning stability

- High-stiffness light recoater to ensure recoating accuracy and efficiency

- Compensation algorithm for multi-head system, ensuring uniform curing in the printing range

Ideal Applications

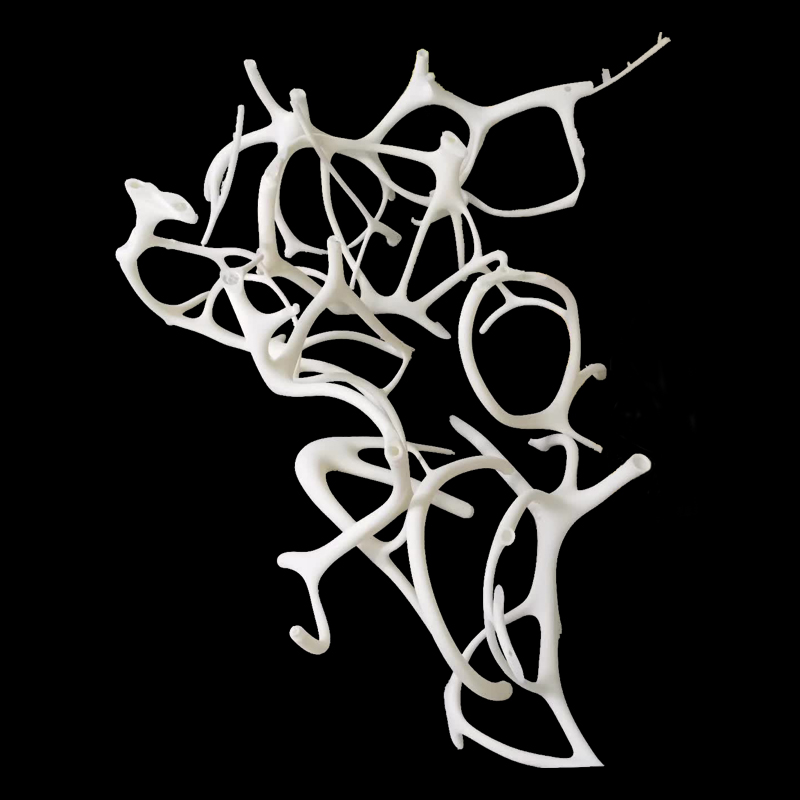

The growing and diverse market demand has driven the use of large SLA 3D printers to solve a variety of complex issues including sculpture making, furniture design, toy industry, art crafts, mould manufacturing, landmarks, end-use products for the automotive, transport or marine industry etc.

-

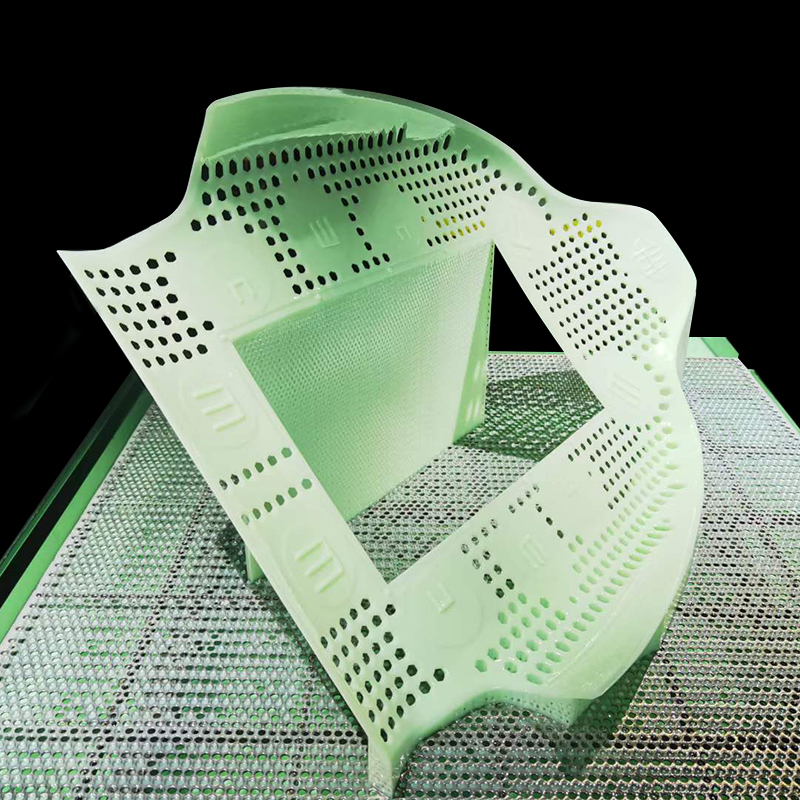

Clear Resins For Prototyping

SLA printers excel at creating clear prototypes that offer unparalleled insight into internal workings. By utilizing translucent resins, these printers produce prototypes with exceptional clarity, enabling users to easily visualize intricate details and diagnose potential issues. This transparency empowers engineers and designers to iterate more effectively, leading to refined and optimized final products.

.jpg)

-

Short Lead Time Mould Manufacture

Traditional methods of manufacturing moulds from aluminium or steel typically require a lengthy cycle of 1 to 2 months. In contrast, large format SLA 3D printers dramatically reduce this timeframe to just 1 to 2 weeks. This accelerated process aligns mould production more closely with the pace of product design updates, significantly reducing the overall design and research & development period for businesses. Consequently, this method enhances workflow efficiency, particularly in the realm of creative projects, leading to faster realization of finished products. Large-format resin 3D printing plays a crucial role in this improved process by enabling the rapid production of moulds with complex geometries that would be time-consuming and expensive to create using traditional methods. This technological advancement not only speeds up production but also encourages innovation by allowing for more frequent iterations and updates in product design

(1).jpg)

-

Product Models and Prototyping

By utilizing high-resolution laser beams to solidify liquid resin layer by layer, SLA printers can produce intricate and accurate models that closely resemble the final product. This capability allows designers and engineers to quickly iterate and test designs, validate concepts, and refine details before moving to production. Additionally, the flexibility of SLA materials enables the production of functional prototypes for testing mechanical properties and fit, further streamlining the product development process. Fit testing for ergonomic applications is ideal for SLA printing allowing fine adjustments to prosthetics dental retainers and other medical devices.

Image Gallery

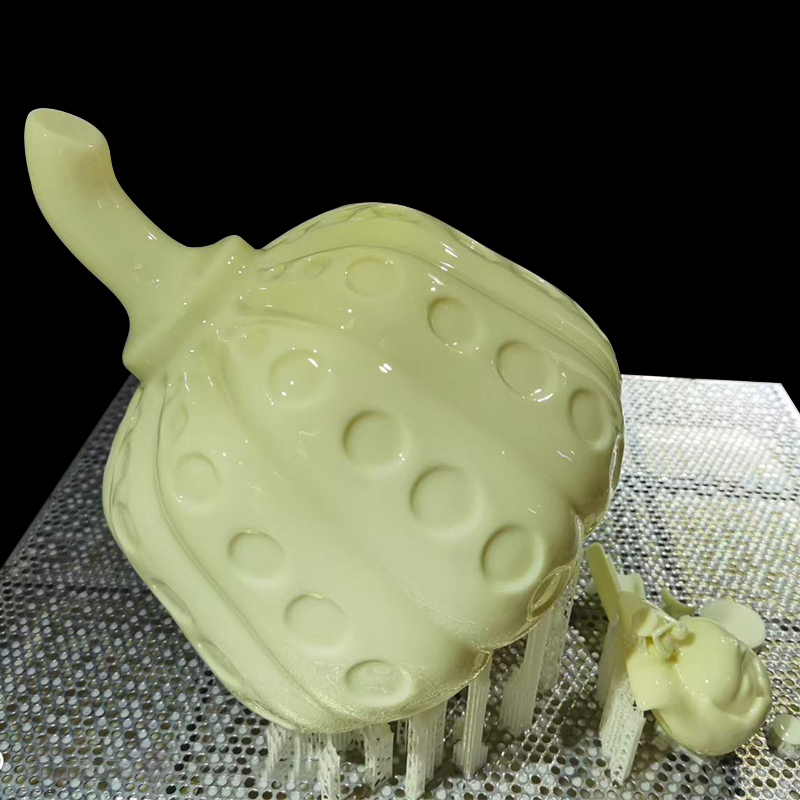

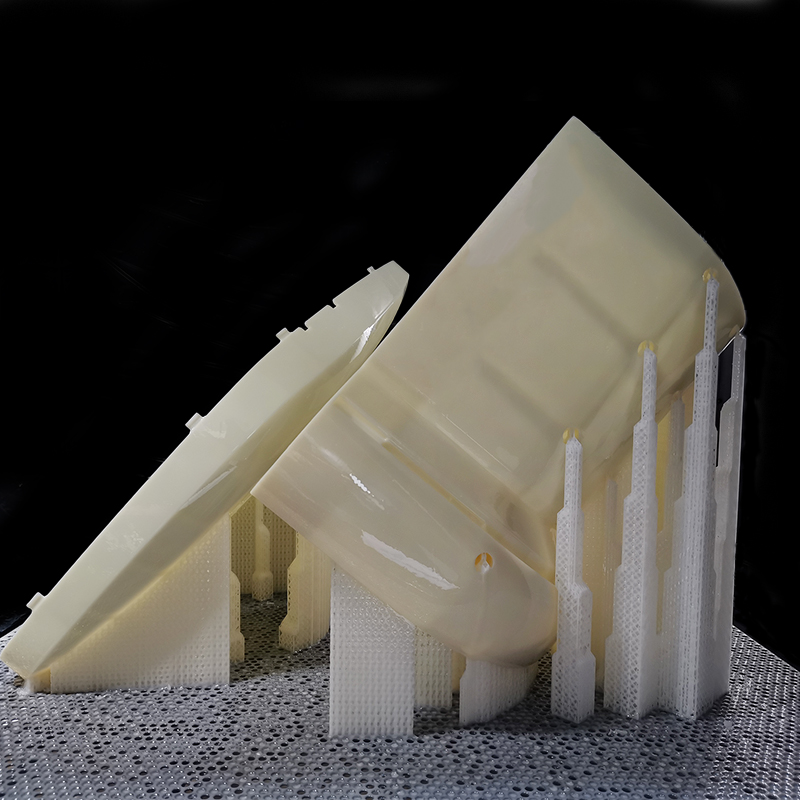

Below are examples of completed projects utilising the large build volume of the Kings 800 Pro 3D Printer.

.jpg)

.jpg)

.jpg)

Technical Specifications

| General information | |

|---|---|

| Printing technology | Stereolithography |

| Printing material | 355nm Resin |

| Build Dimensions | 800 x 800 x 500cm |

| Printer Dimensions | 1400 x 1490 x 2470mm |

| Laser Type | Solid State freq tripled Nd: YV04 |

| Weight | 1900kg |

| Wavelength | 355nm |

| Max Scanning Speed | 15.0m/s |

| Beam Size | 0.075-0.8mm |

| Layer Thickness | 0.05 - 0.25mm |

| Resin Tank Volume | 500kg |

| Vertical Resolution Accuracy | 0.0005 |

| Power | |

|---|---|

| Power supply | 240v AC |

| Rated Power | 1.8 KVA |

| Power Type | Single Phase |

Who is Kings Printing?

Kings 3D is a leading additive manufacturing company in China, dedicated to the R&D, Applications and innovation of 3D printing. Kings 3D provides complete ranges of plastic and metal printers, 3d printing materials and industrial Applications solutions. They are one of the largest industrial printer manufacturers in China. 3DPrinter gear is the exclusive supplier for Kings Printers in Australia.

Kings 3D is at the forefront of shaping the entire additive space that spans everything including prototyping, automotive, aerospace, medical, footwear, jewellery, home appliance etc. Kings 3D envisions a world in which ideas become reality through 3D printing technology. And it is where Kings 3D thrives.

(KINGS-800Pro)

| SKU | KINGS-800Pro |

| Brand | Kings |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.