Formlabs BioMed Amber Resin

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

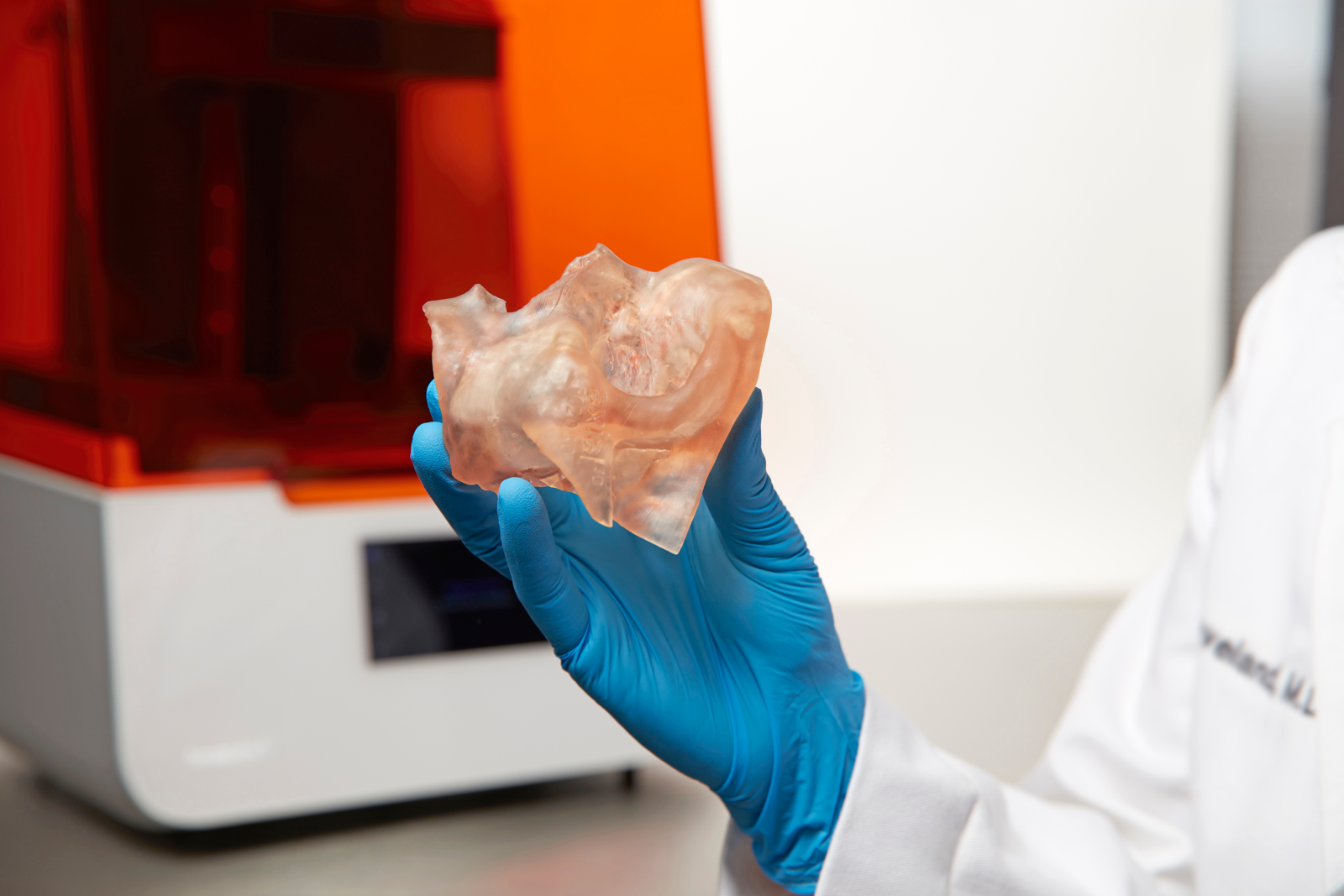

Formlabs BioMed Amber Resin

A strong, stiff biocompatible resin for printing rigid, sterilizable parts for medical R&D, device production, and point-of-care applications.

Why choose BioMed Amber Resin?

Medical-grade material

Produced under ISO 13485 quality management, supporting better traceability and confidence for medical teams.

Biocompatible + sterilizable

Tested for common disinfection and sterilization workflows that medical teams commonly rely on.

Semi-transparent with high definition

Useful when visibility through the part is needed, while still delivering strong mechanical performance.

Applications

Designed for rigid, biocompatible parts where strength, stiffness, and sterilization compatibility matter.

- End-use medical devices and device components

- Implant sizing models

- Cut, drill, or surgical guides

- Specimen collection kits

Workflow overview

Standard SLA sequence of wash → dry → post-cure, but with strict discipline for biocompatible use: dedicated validated equipment, following the Manufacturing Guide/IFU, and internal validation for your use case.

Typical validated post-processing summary

- Wash: IPA in validated wash unit — until clean per guide.

- Dry: Air dry adequately before curing.

- Post-cure: In validated unit per specified cycle.

Best practice: Always follow the official Manufacturing Guide/IFU for your exact equipment and workflow.

Sterilization & disinfection

Compatibility data is provided to guide use with common sterilization and disinfection approaches. Full details are in the TDS and Manufacturing Guide.

- Autoclave, gamma, E-beam, EtO, and IPA disinfection methods are addressed in documentation.

Important: Material properties vary with geometry, settings, and sterilization method. Validate your full process for each application.

Tech specs at a glance

Tip: Use the official Manufacturing Guide/IFU for validated settings and sterilization compatibility ranges.

Downloads & documentation

(70763)

| SKU | 70763 |

| Brand | Formlabs |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.