Formlabs Rigid 10K Resin

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

Formlabs Rigid 10K Resin (Form 4)

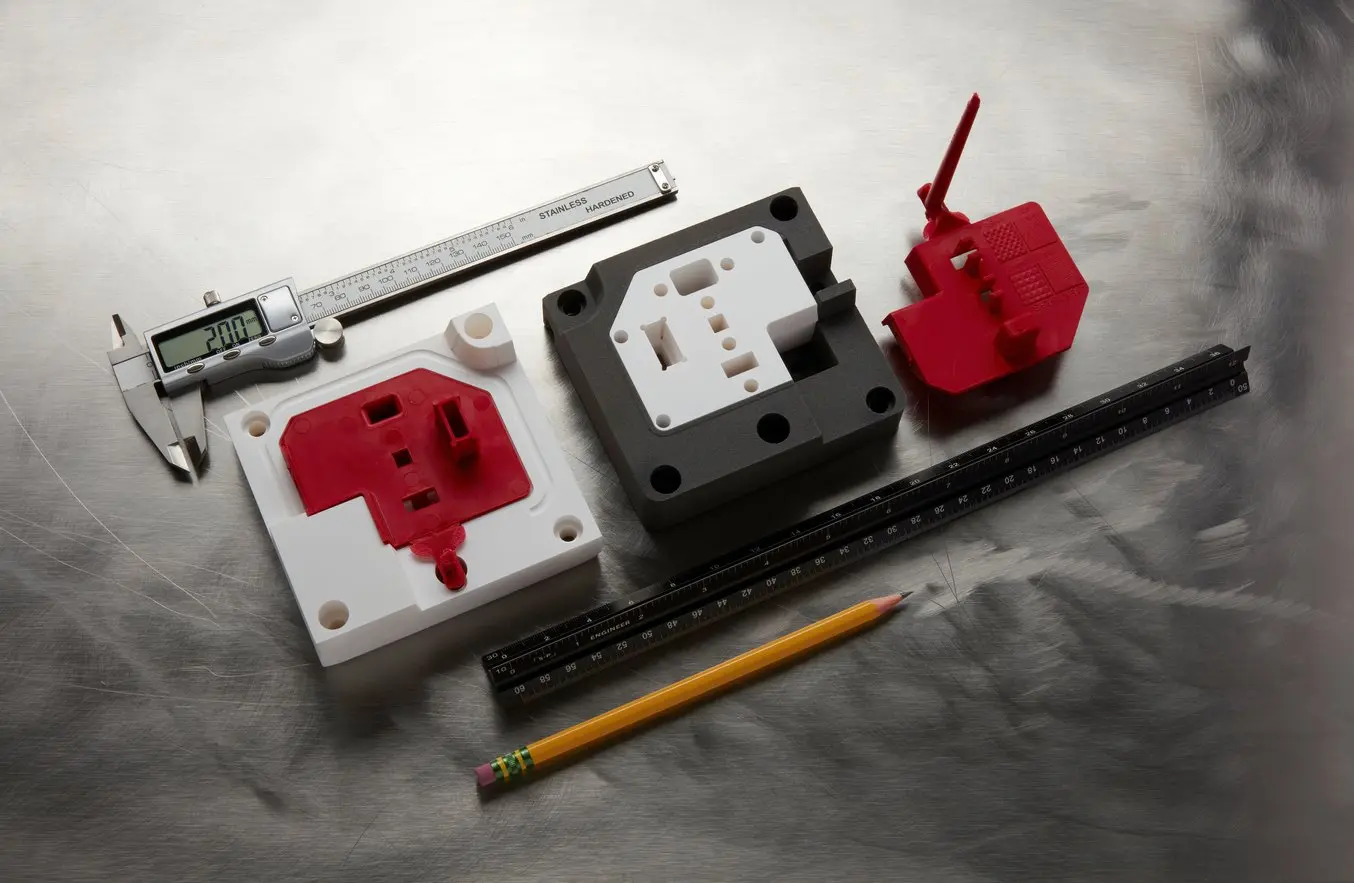

A highly glass-filled engineering resin for producing extremely stiff, strong, industrial-grade parts with a smooth matte finish — ideal for tooling, molds & inserts, and heat/chemical-resistant components that must hold shape under load.

Why Choose Formlabs Rigid 10K Resin?

Extremely Stiff

Glass-filled reinforcement delivers maximum stiffness for parts that must resist bending and deflection.

Heat & Chemical Resistance

Suitable for components exposed to elevated temperatures and a range of fluids and chemicals.

Precise Tooling Geometry

Print accurate molds, inserts, and fixtures with crisp detail and a smooth matte finish.

Faster Than Machining for Iteration

Accelerate design-test cycles for tooling and industrial prototypes without machining lead times.

Applications

Rigid 10K Resin is designed for industrial use cases where stiffness, stability, and surface quality are key.

Consider Rigid 10K Resin for:

- Short-run injection mold masters and inserts

- Jigs, fixtures, and manufacturing aids

- Heat-resistant and fluid-exposed components

- Aerodynamic test models and rigid flow fixtures

Tip: For tooling and inserts, design with generous fillets and avoid sharp internal corners to reduce stress concentration.

Workflow Overview

Rigid 10K Resin follows a standard print + wash + post-cure workflow. Use the manufacturer-recommended settings and post-processing steps to achieve intended stiffness and stability.

- Print using the Rigid 10K Resin preset for your Form 4 printer.

- Wash using the validated cleaning method and timings.

- Post-cure using the validated cycle for full mechanical performance.

- Finish (support removal, light deburr) while preserving critical mating surfaces.

Downloads & documentation

(70852)

| SKU | 70852 |

| Brand | Formlabs |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.