Kings M100D

1200*800*1700mm

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

$10 Flat Rate Shipping - $10.00

- Delivery in 2-7 Business Days.

- Most Economical Option

- Australia Wide

- Online Tracking Available

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

Kings M100D SLA Industrial 3D Printer

Advanced Large Format Solutions from 3D Printer Gear

In SLM printing, a high-powered laser selectively melts and fuses powdered material (usually metals such as aluminum, titanium, stainless steel, etc.) layer by layer according to a 3D digital model. This process enables the creation of complex and intricate metal parts directly from digital designs.

The process begins with a thin layer of metal powder spread over a build platform. Then, a laser beam scans the powdered layer, melting and fusing the particles together according to the cross-sectional shape of the desired object. Once a layer is completed, the build platform descends by the thickness of one layer, and the process repeats until the entire object is fabricated.

SLM printing offers several advantages, including the ability to produce highly complex geometries, rapid prototyping, and the manufacture of parts with high strength and durability. It's commonly used in industries such as aerospace, automotive, medical, and engineering for producing components with specific material properties and intricate designs.

Watch the full print process

Features

- High-precision scanning galvanometer ensure high precision and strong stability

- Dual circulation wind site protection system: Dual-circulation

wind site protection system to extend the lifespan of the optical

components - Fully pop-up piston system: Equipped with a fully pop-up piston

system, it is more convenient and quicker to replace metal

powders, and 100% eliminates cross powder contamination

when replacing powders - All closed looped powder handling system: The low oxygen

content in the manufacturing environment ensures that the

metal is not oxidized, and is compatible with powders of

different specifications

Ideal Applications

SLM printers can create models that are impossible to manufacture with standard manufacturing techniques. Models can be hollow or built with internal channels and components integrated into the design. SLM printing is commonly used in aerospace for reducing part counts and increasing reliability by creating a single part with coolant channels ducting and electrical components all integrated into one part.

-

Rapid Prototyping

SLM printers are highly effective for rapid prototyping due to their ability to swiftly produce intricate designs with minimal setup time. By fabricating parts layer by layer, these printers significantly reduce lead times compared to traditional manufacturing methods, making them ideal for quickly iterating on designs. Moreover, SLM technology enables the creation of complex geometries that would be challenging or impossible to achieve through conventional means, offering designers the freedom to explore innovative concepts without constraints. Additionally, SLM printers provide the flexibility to work with various metals, allowing engineers to prototype parts with specific material properties tailored to their requirements. While there may be higher upfront costs, the long-term cost-effectiveness of SLM printing, coupled with the ability to identify and address potential issues early in the development process, makes it a valuable tool for rapid prototyping across industries.

-

Jewelry design

SLM printers revolutionize the jewelry-making process by offering unparalleled precision and versatility. With these printers, intricate and customizable jewelry designs can be brought to life efficiently and with exceptional detail. The layer-by-layer fabrication method allows for the creation of complex geometries, intricate patterns, and delicate filigree work that traditional manufacturing techniques struggle to achieve. Jewelry designers can explore innovative concepts and experiment with various materials, including precious metals like gold, silver, and platinum. This technology enables the production of bespoke pieces tailored to individual preferences, whether it's personalized pendants, intricate earrings, or unique rings. While SLM printing may require initial investment, its ability to streamline production, minimize material waste, and deliver high-quality, customizable jewelry makes it an invaluable tool for modern jewelry design and manufacturing.

-

Healthcare

SLM printers offer transformative capabilities in healthcare and dental applications, advancing both patient care and manufacturing processes. In healthcare, these printers facilitate the creation of patient-specific implants, prosthetics, and surgical instruments with unmatched precision and customization. Surgeons can leverage SLM technology to produce implants tailored to the unique anatomy of individual patients, leading to improved outcomes and reduced recovery times. Dental laboratories benefit from SLM printing by fabricating highly accurate crowns, bridges, and dental frameworks, streamlining production and ensuring optimal fit and functionality for patients. Additionally, SLM printers enable the fabrication of intricate dental models for treatment planning and educational purposes. The ability to work with biocompatible materials ensures that the final products meet stringent regulatory standards and provide safe, reliable solutions for patients. Overall, SLM printers are driving innovation in healthcare and dental industries, empowering practitioners to deliver personalized, high-quality care while enhancing manufacturing efficiency and quality control.

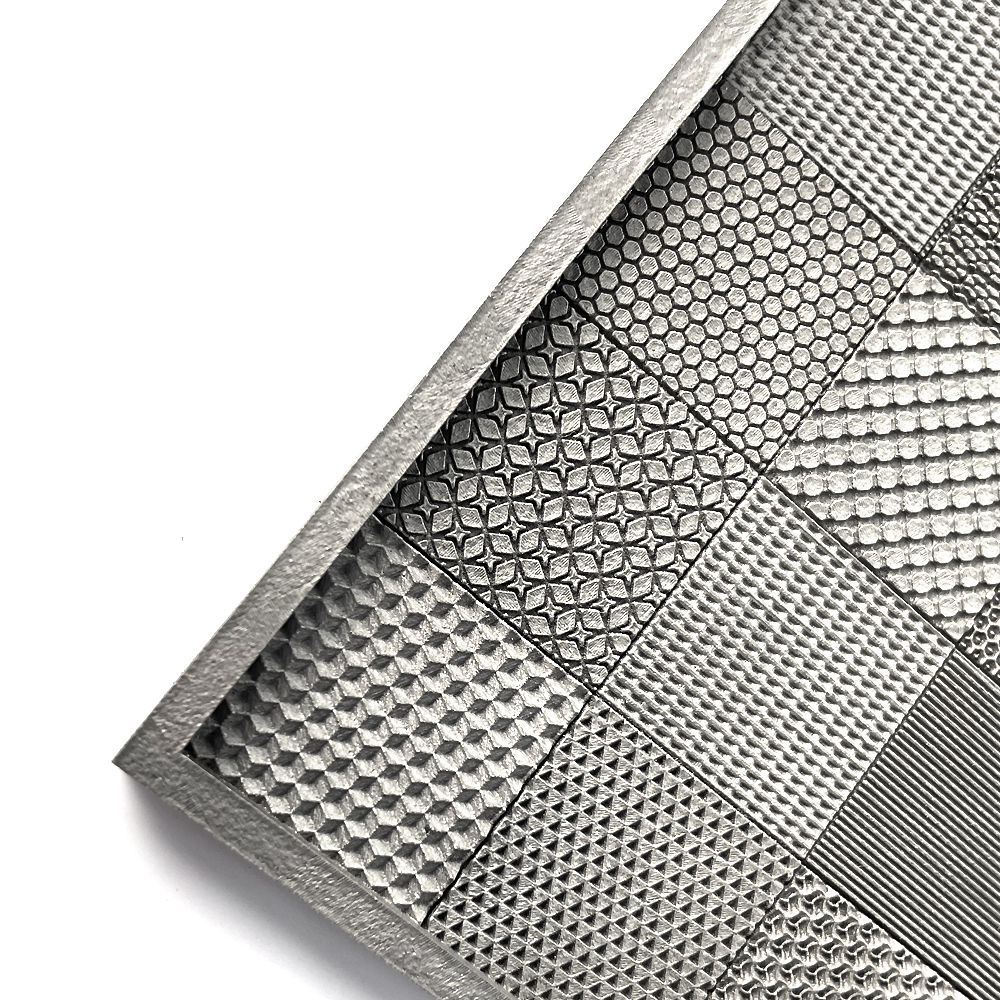

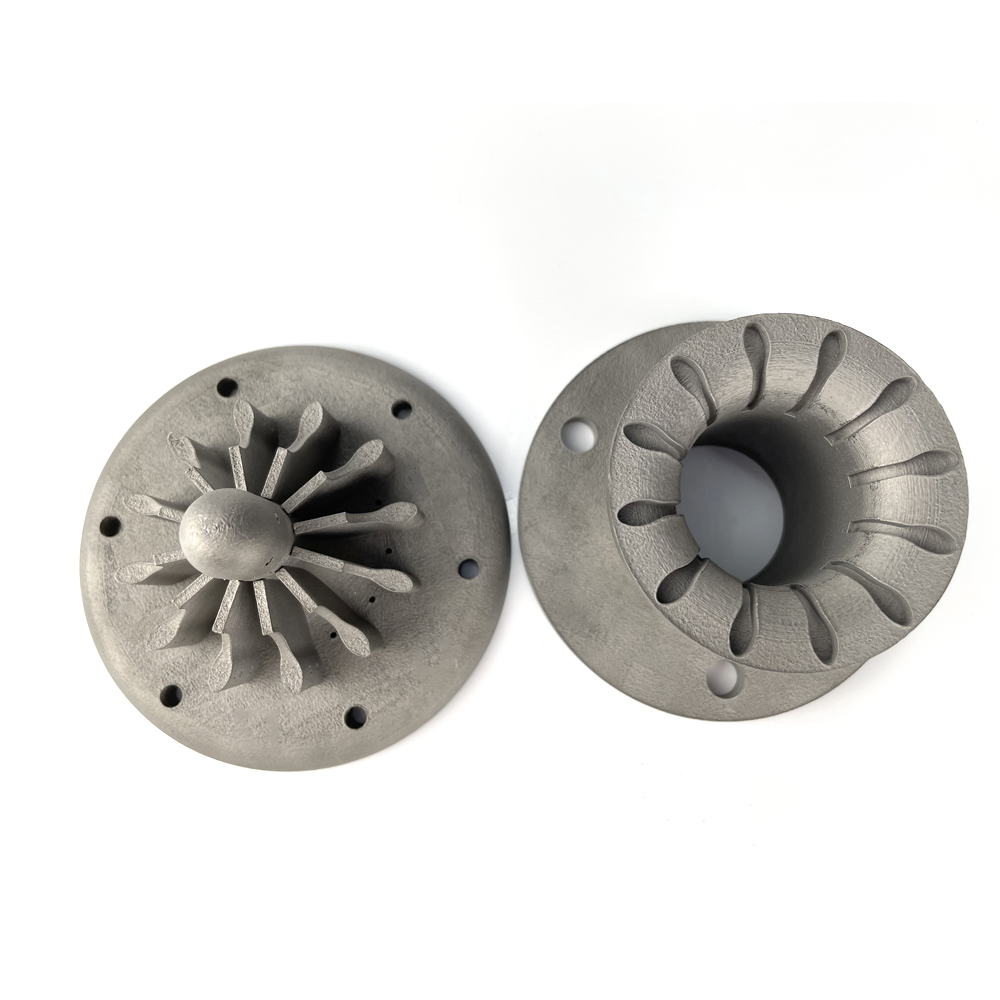

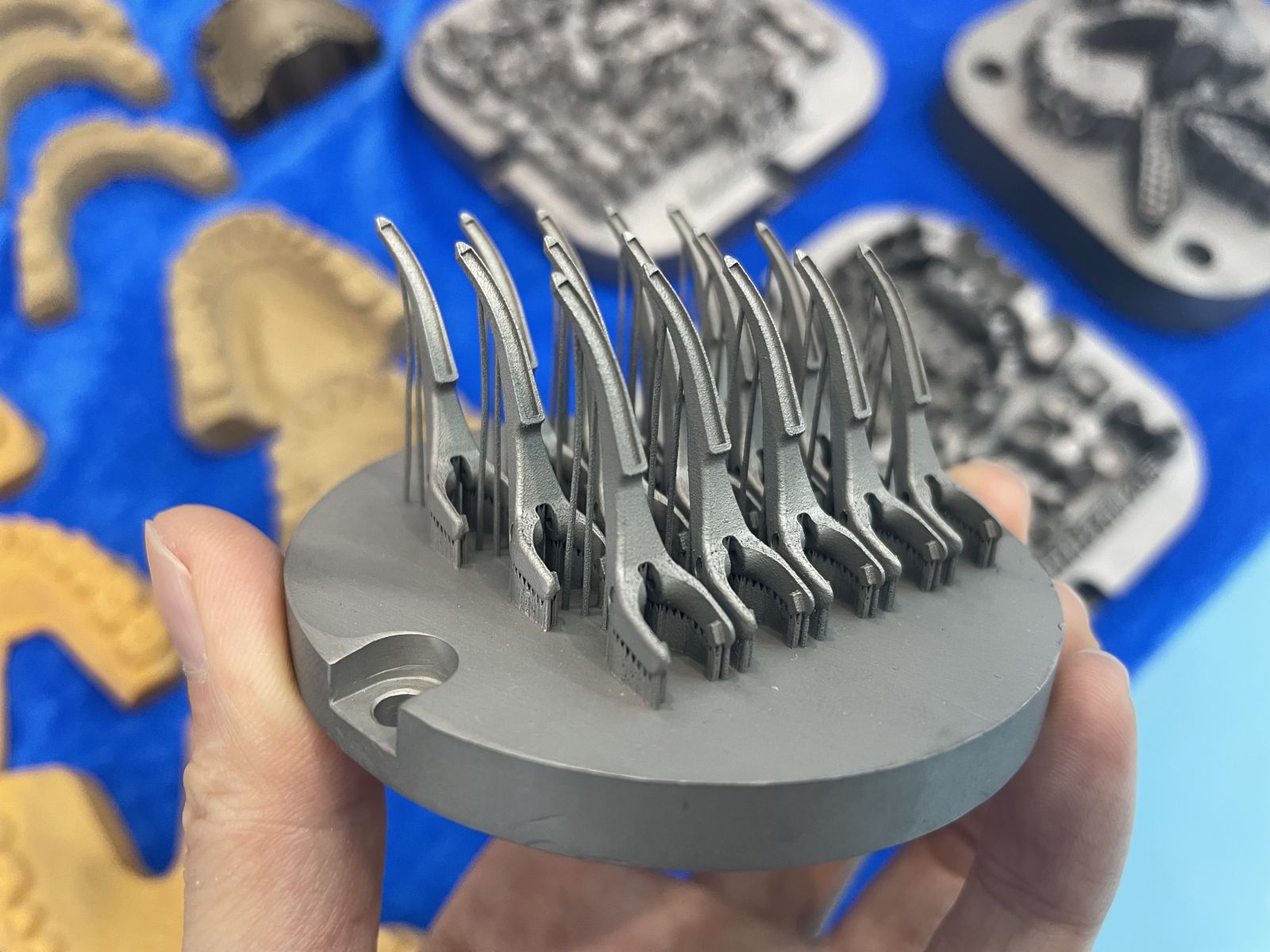

Image Gallery

Below are examples of completed projects utilising SLM printers.

Technical Specifications

| General information | |

|---|---|

| Printing technology | Selective Laser Melting |

| Printing material | 316L,Ti6AI4V,AISi10Mg,In 718, CuSn10, CoCr,18Ni300 etc, more materials |

| Build Dimensions | 120x120x120mm |

| Printer Dimensions | 1200*800*1700mm |

| Laser Type | Dual IPG Lasers, 2×500W |

| Max Scanning Speed | 15m/s |

| Powder Delivery | Double Cylinder One Way Powder Feeding |

| Layer Thickness | 0.02 - 0.1mm |

| Inert Gas Protection | Nitrogen/Argon |

| Power | |

|---|---|

| Rated Power | 220V AC 50/60HZ 32A Single Phase |

(KINGSM100D)

| SKU | KINGSM100D |

| Brand | Kings |

| Shipping Weight | 1.0000kg |

| Shipping Width | 1.200m |

| Shipping Height | 1.700m |

| Shipping Length | 0.800m |

| Unit Of Measure | each |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.