Original Prusa XL Assembled 3D Printer - 2 Toolhead

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

ORIGINAL PRUSA XL Assembled With 2 Tool Changers

The Original Prusa XL runs on the latest embedded 32-bit platform with support for ultra-fast printing thanks to the native implementation of Input Shaper and Pressure Advance. Combined with the next-generation extruder, Nextruder, and its Loadcell sensor, the system can deliver an always-perfect first layer across the entire print surface - even in the five-head configuration! While the printer is compatible with our Prusa Connect network solution, it can be fully operated offline without any sacrifices in user comfort.

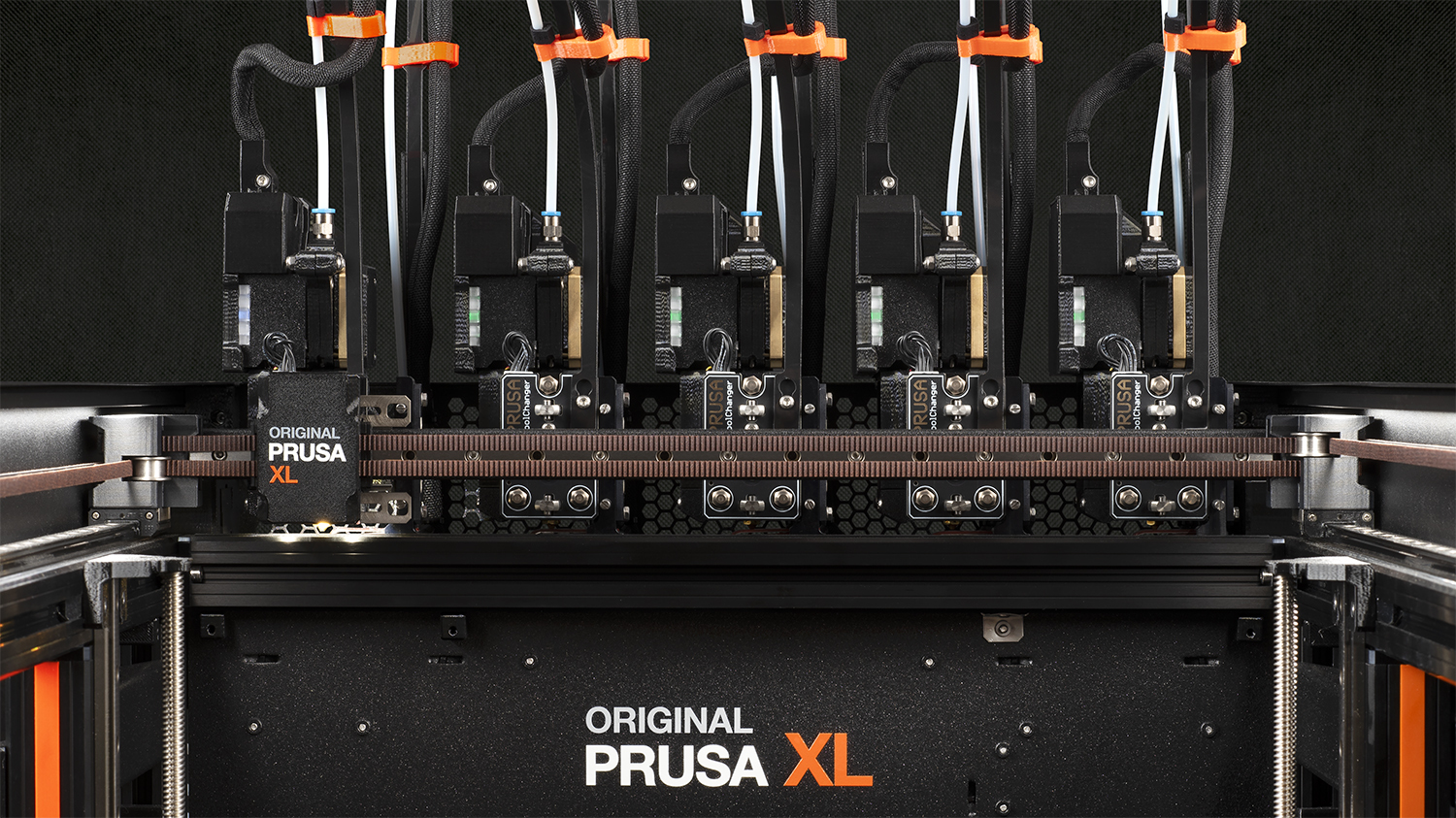

The toolchanger is what really sets the Original Prusa XL apart from other CoreXY 3D printers. The printers configuration allows for docking up to five toolheads and switching between them in a blink of an eye. You can preload up to five different filaments and truly take advantage of full multi-material printing. PLA combined with FLEX? PETG with PLA supports? The Original Prusa XL can deliver stunning results with ease - fast!

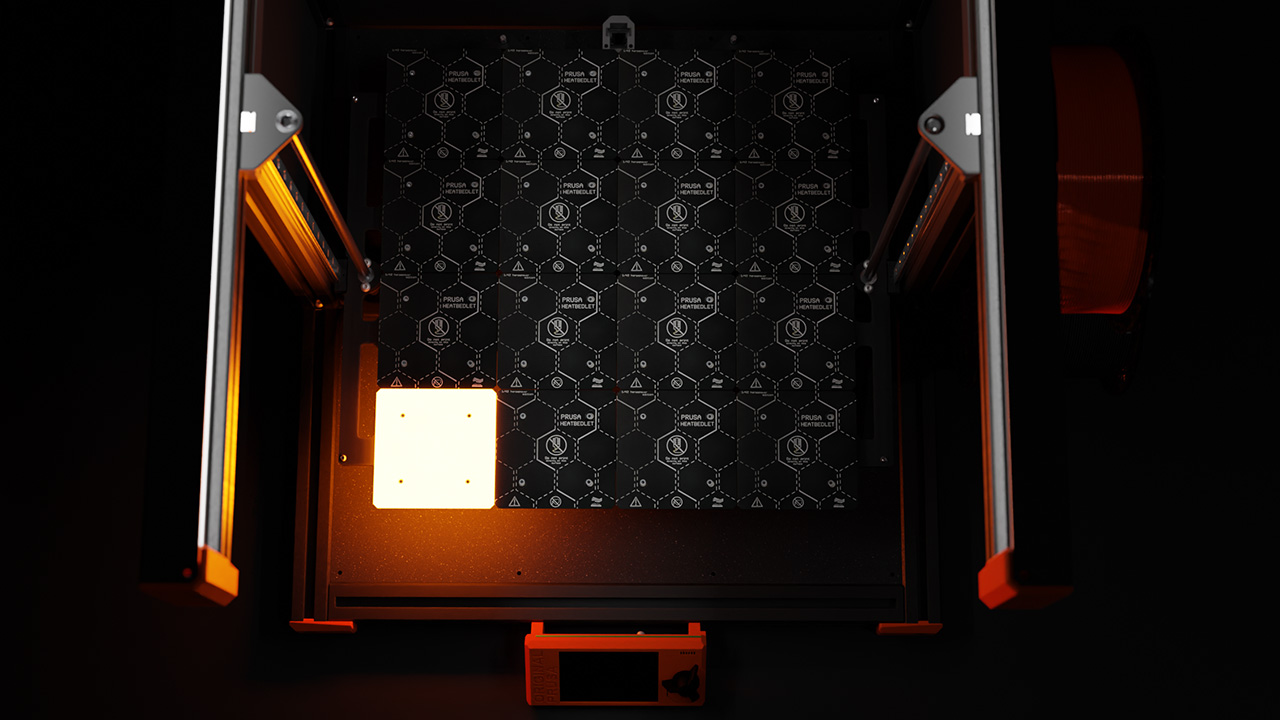

To further improve the quality and reliability of printing, the XL is equipped with a modular segmented heatbed driven by a separate electronic board. The heatbed consists of 16 individually controlled tiles designed to prevent heat deformation which is usually present in printers with a single large heatbed. You can always find the perfect print surface for your material with our proven double-sided print sheets with various types of surface textures.

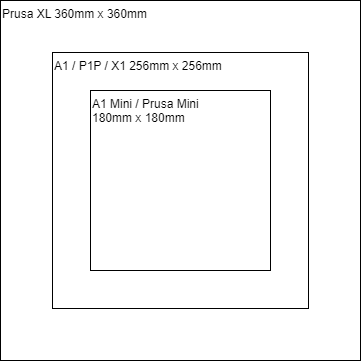

With eight times larger print volume compared to the MINI+, no project is too big for the XL!

The Prusa XL Review - 3D Printing Nerd

FREQUENTLY ASKED QUESTIONS

Q: What is the difference between the Prusa XL and the X1E/X1C?

A: Both the Bambu Lab X1E and the Prusa XL are premium professional-grade printers. The Prusa XL features a larger build volume than the X1E at 360mm cube vs 256 mm cube. The X1E however does have a fully enclosed heated camber that has active heating controls allowing users to print high-performance engineering filaments. The Prusa XL has no enclosure which makes printing Nylon ABS and Polycarbonate nearly impossible. Both can print with multiple materials at once however the Prusa XL prints with separate nozzles for each part allowing the use of different temp materials in the same print. This also allows the XL to print soluble supports, and hybrid flexible parts with faster material changes than the X1E.

Q: What are the advantages of the Prusa Tool changer vs the Bambu AMS unit?

A: Reduced filament waste. Parts typically have less than 10% waste with multi-material prints compared to over 100% for many AMS multi-material prints.

Much faster print times with multiple materials as much as 4 to 6 times faster for prints with many material changes

Better performance with flexible materials with reduced travel distance for filament path and only one load/unload process

Q: Is the Prusa XL suitable for beginners?

A: The Prusa XL is primarily designed for professionals and advanced users as it allows for more complex multi-material parts. Its design, including enhanced connectivity options and advanced material handling capabilities, seems tailored toward users who have a good understanding of 3D printing technology. However, it doesn't mean a beginner couldn't learn to use it, especially with the right guidance and willingness to learn. 3D Printer Gear can also provide training for staff or any buyers who are not experienced with 3D printing.

Q: Can I print ultra-high-temperature materials on the Prusa XL?

A: Prusa XL, with a maximum hot-end temperature of 300°C, falls short of the required temperature range for printing ultra-high-temperature materials like PEKK (340°C to 360°C) and PEI (355°C to 390°C). Therefore, it is not suitable for printing these materials.

Q: Why is it cheaper on the Prusa website?

A: At 3D Printer Gear, we provide local support and assistance, including in-house warranty and repair services. This means that if you encounter any issues with your printer or require printing assistance or advice, we can provide immediate support via phone, email, or video chat or you are always welcome to bring your printer into our showroom. At 3D Printer Gear, we provide the added value of local support and assistance to ensure a hassle-free experience for our customers. You do not need to spend hours scouring the internet for help - we're here to provide you with design guidelines, help with slicing setup/optimisation, and offer general 3D printing advice for whatever your needs may be. We're not just a supplier, we're your partner in this 3D printing journey.

Why buy printers from "3D PRINTER GEAR"?

Since 2012, 3D Printer Gear is Australia's leading supplier of 3D printers, filaments, resins, and 3D scanners to Australian businesses, schools, and hobbyists.

We are passionate about 3D printing in Australia and the limitless opportunities additive manufacturing can provide to everybody. All our products go through rigorous testing in our in-house 3D printing farm before they are listed on our website so you also gain expert advice on 3D printing setup calibration and techniques.

From the home user working on their latest invention, mining and military applications, or supplying the many schools and universities around Australia, our focus is to provide quality 3D printing material and expert 3D printing advice at a competitive price.

Prusa XL Specs vs Bambu Lab X1E

| Prusa XL | X1E | |

|---|---|---|

| Wi-Fi | Frequency Range: 2400 MHz - 2483.5 MHz WPA2-Enterprise: No |

Frequency Range: 2400 MHz - 2483.5 MHz WPA2-Enterprise: EAP-PEAP EAP-TLS TAP-TTLS |

| Ethernet | Socket: RJ45 Speed: 100 Mbps / Full Duplex |

Socket: RJ45 Speed: 100 Mbps / Full Duplex |

| Supported Filaments | PLA, PETG, TPU, PVA, BVOH: Optimal ABS, ASA, PC, PA, PET: Not Recommended Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA: Not supported PPA-CF/GF, PPS, PPS-CF/GF: Not supported |

PLA, PETG, TPU, PVA, BVOH: Optimal ABS, ASA, PC, PA, PET: Superior Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA: Superior PPA-CF/GF, PPS, PPS-CF/GF: Ideal |

| Chamber Heating | Active Chamber Heating: N/A Maximum Chamber Control Temperature: N/A |

Active Chamber Heating: Yes Maximum Chamber Control Temperature: 60? |

| Air Purification | No Fume Filter | Pre-filter grade: G3 HEPA filter grade: H12 Activated Carbon Filter type: Coconut Shell Granulated VOC Filtration: Optimal Particulate Matter Filtration: Yes |

| Network Control | Wifi Pre-installed | Ethernet: Yes Wireless Network: Wi-Fi Network Kill Switch: Wi-Fi & Ethernet Removable Network Module: Yes 802.1X Network Access Control: Yes |

| Toolhead | Hot Ends: 5x All-Metal Nozzle: Brass Max Hot End Temperature: 300? |

Hot End: All-Metal Nozzle: Hardened Steel Max Hot End Temperature: 320? |

| Heatbed | Build Plate: Flexible Steel Plate Max Temp: 120 degrees C 16x Individual heat bed tiles, energy-efficient when printing small objects |

Build Plate: Flexible Steel Plate Build Plate Surface (Included): Bambu Smooth PEI Plate Max Build Plate Temperature: 110?@220V? 120?@110V |

| Speed | Slower speed printing however faster speed multi-material printing due to quick tool changes | Max Speed of Toolhead: 500 mm/s Max Acceleration of Toolhead: 20000 mm/s2 |

| Sensors | Build Chamber Camera: No Loadcell sensor |

Bambu Micro Lidar: Yes Chamber Monitoring Camera: 1920*1080 Included |

| Build Volume | 360 x 360 x 360 mm | 256 × 256 × 256 mm |

| Physical Dimensions | 800×800×900* mm 25.3kg including side spool holders and top enclosure cover (separate future add-on) | Dimensions: 389*389*457 mm³ Net Weight: 16kg |

(PRUSA_XL_2T)

| SKU | PRUSA_XL_2T |

| Brand | Prusa Research |

| Shipping Weight | 30.0000kg |

| Shipping Width | 0.700m |

| Shipping Height | 0.600m |

| Shipping Length | 0.600m |

| Shipping Cubic | 0.252000000m3 |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.