Bambu Lab H2S 3D Printer

or 4 payments of $474.75 with

Info

Info

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

BAMBU LAB H2S 3D PRINTER

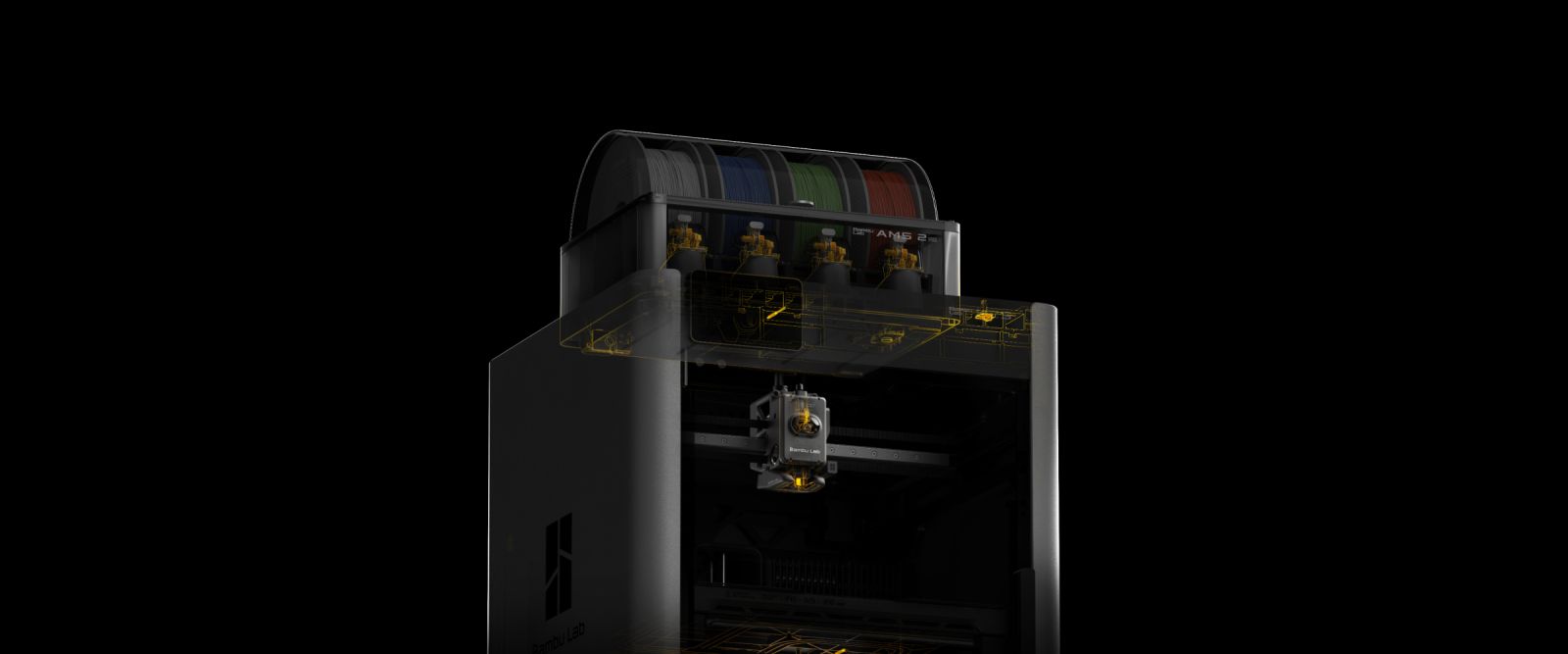

BUILT FOR SPEED, CREATIVITY & VERSATILITY

The Bambu Lab H2S 3D Printer is designed for creators and professionals who demand speed, precision, and flexibility. With support for high-temperature materials, advanced composite printing, and optional laser and cutting modules, the H2S goes beyond 3D printing to unlock new creative and prototyping possibilities. Experience rapid production, reliable performance, and outstanding print quality in one powerful system.

Product Features

- 350℃ (662°F) High-Temperature Hardened Steel Nozzle

- 1000 mm/s Maximum Print Speed with 20,000 mm/s² Acceleration

- 65℃ (149°F) Active Chamber Heating

- Multi-Camera Monitoring (Live View, Toolhead, optional BirdsEye)

- Closed-Loop Cooling Fans for Stable Print Quality

- Wi-Fi Connectivity for Simple Integration

- Advanced Air Filtration (G3, H12 HEPA, Activated Carbon)

- Optional 10 W Laser Module for Engraving & Cutting

- Optional Cutting Module for Paper, Vinyl, Leather & More

Your Go-To Personal Manufacturing Hub

Accuracy That Works for You

Correct Mechanical Deviations

Even the printer come out of the factory with superb accuracy, mechanical wear and variances over time are inevitable—but now, first time in the industry, there’s a solution. With the Vision Encoder⁽¹⁾, the H2S achieves distance-independent motion accuracy under 50 μm—thinner than a human hair. During calibration, it automatically compensates for mechanical drift, ensuring consistent precision and peak performance over time.

One Print. Perfect Fit

Bambu Lab's Auto Hole/Contour Compensation² minimizes printing tolerances, delivering machine-shop-level precision for hole dimensions. Design fit-critical parts with confidence—integrate shafts, bearings, and fasteners without trial and error. Post-print assembly has never been easier.

High-Temperature 350 °C HotendPush the limits with engineering-grade filaments. From PLA and PETG to PC and PPA, the 350 °C hotend unlocks a broader material range. Combined with closed-loop fan control and precise thermal regulation, it delivers consistent flow and optimal extrusion—so parts achieve the strength, heat resistance, and surface quality your projects demand. |

|

|

Actively Heated 65 °C ChamberPrint larger, more demanding parts with confidence. The actively heated 65 °C chamber stabilizes internal temperatures to minimize warping, improve interlayer adhesion, and enhance dimensional accuracy. High-performance polymers become easier to tame, yielding strong, reliable components that hold their shape from first layer to finished part. |

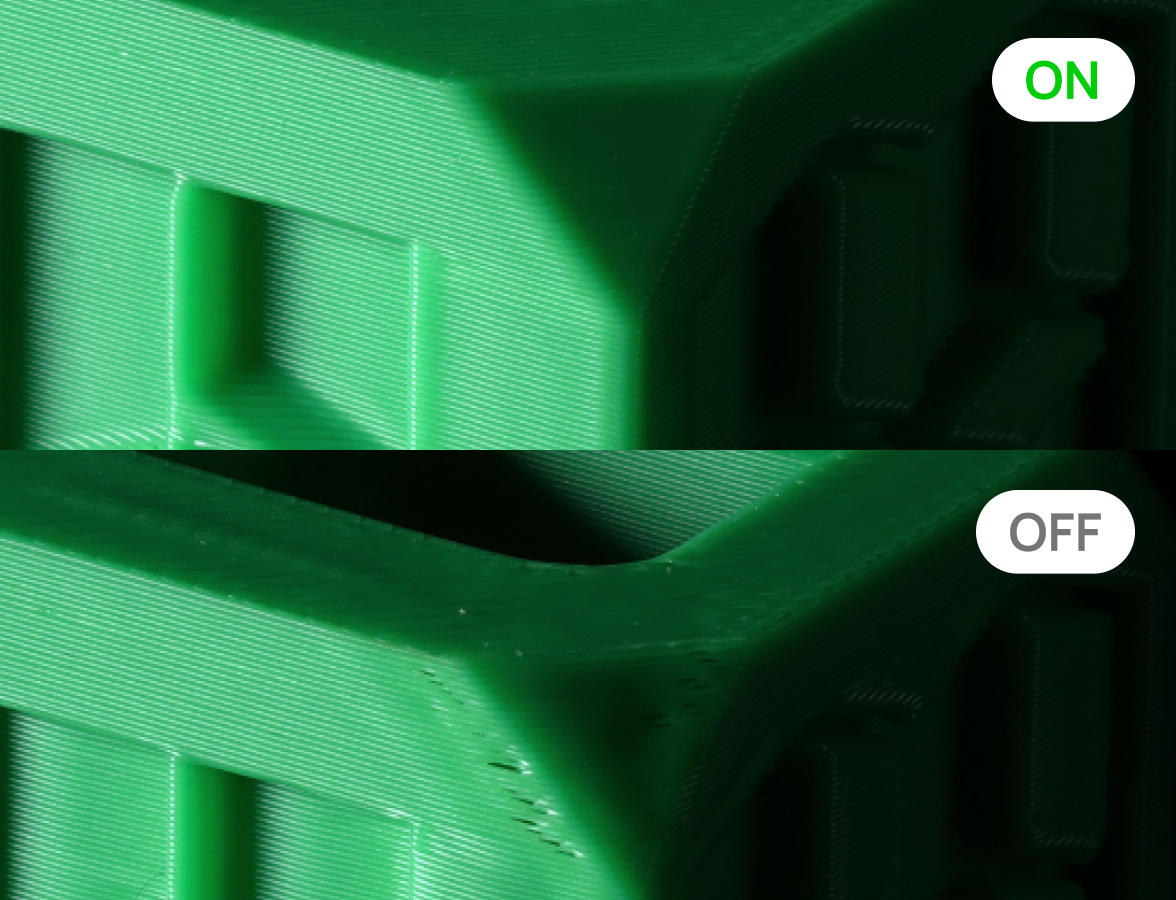

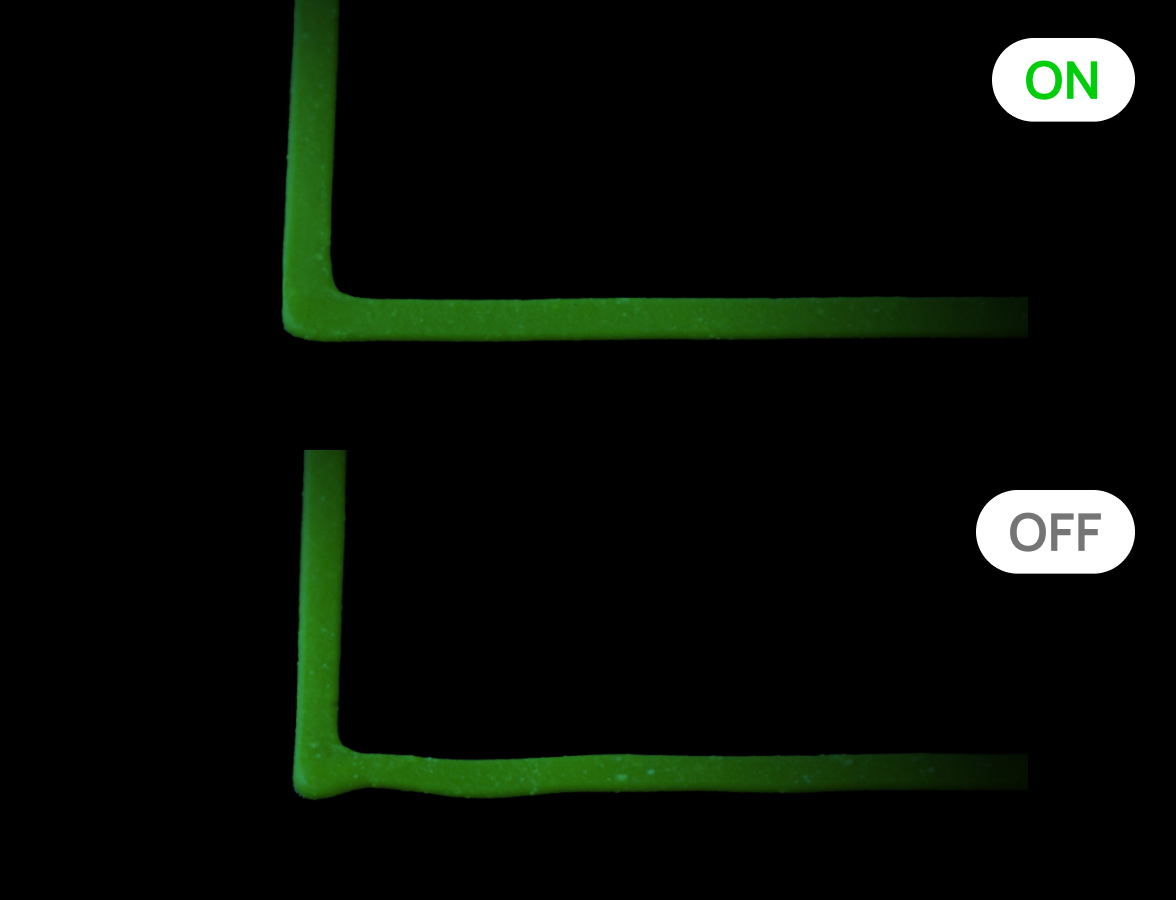

Even Surfaces, Crisp EdgesH2S pairs the sensing capability of its servo-driven extruder with high-resolution eddy-current sensors at the nozzle to precisely manage flow. By inferring nozzle pressure and auto-calibrating pressure advance (PA) for each filament, it reduces over-extrusion at corners, tightens line width control, and delivers smoother walls with razor-sharp edges. |

|

|

Precision in MotionWith Active Vibration Compensation, the H2S continuously detects and counteracts micro-vibrations and resonance in real time. This intelligent control maintains accuracy even at higher speeds, delivering smooth surfaces, sharp details, and premium print quality without sacrificing throughput. |

Intelligence That's Got Your Back

20 Khz Closed-Loop Feedback, Real-Time Control

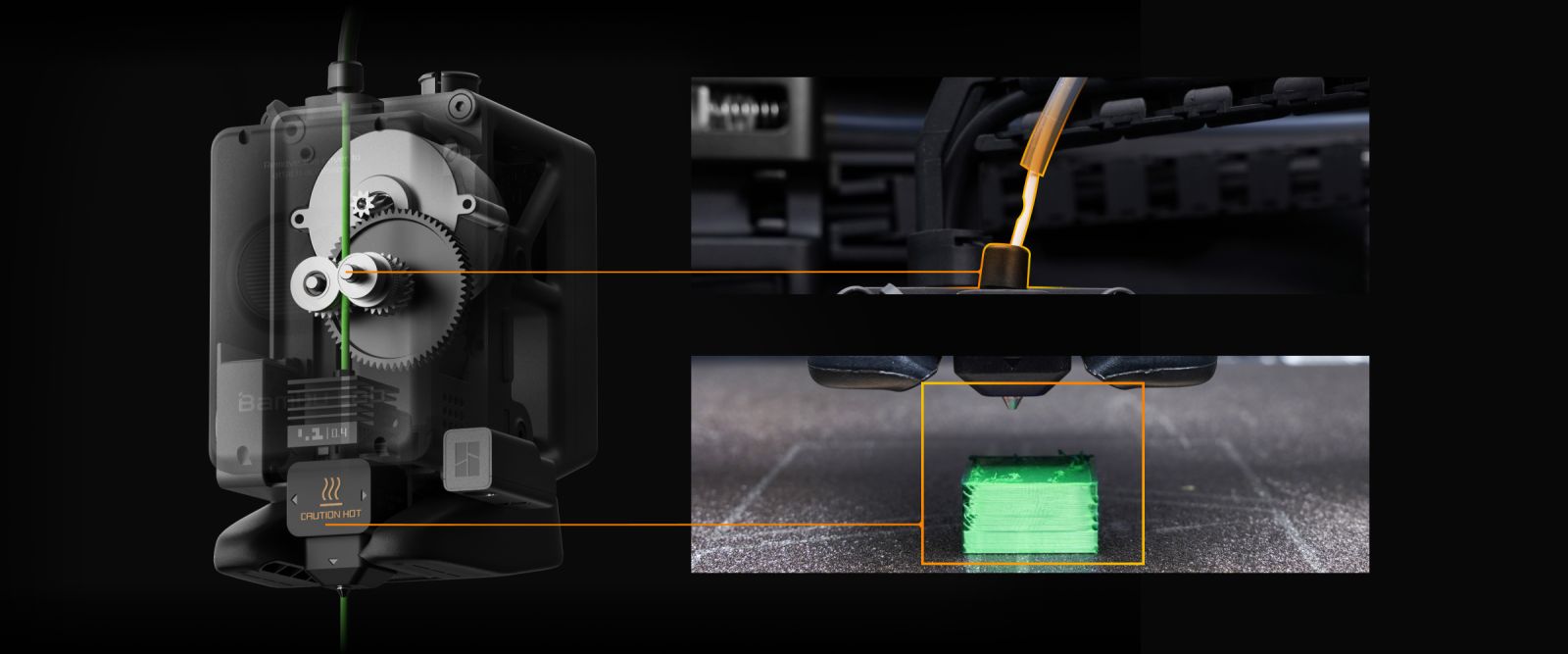

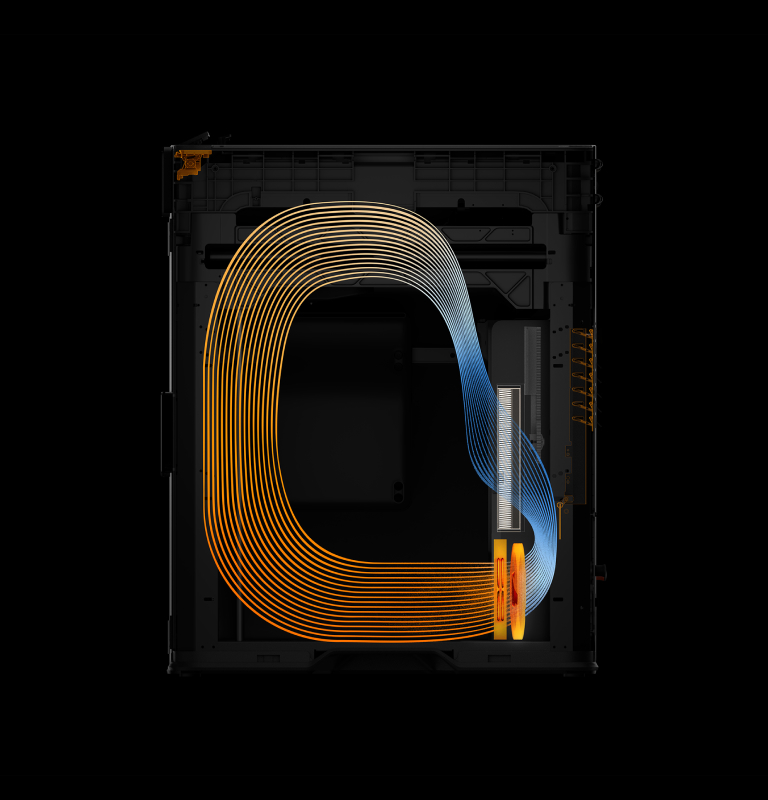

Bambu Lab's proprietary PMSM servo system enables 20 kHz resistance and position sampling to dynamically modulate electromagnetic torque vectors. It stabilizes extrusion and actively detects grinding⁽³⁾ or clogs in real time.

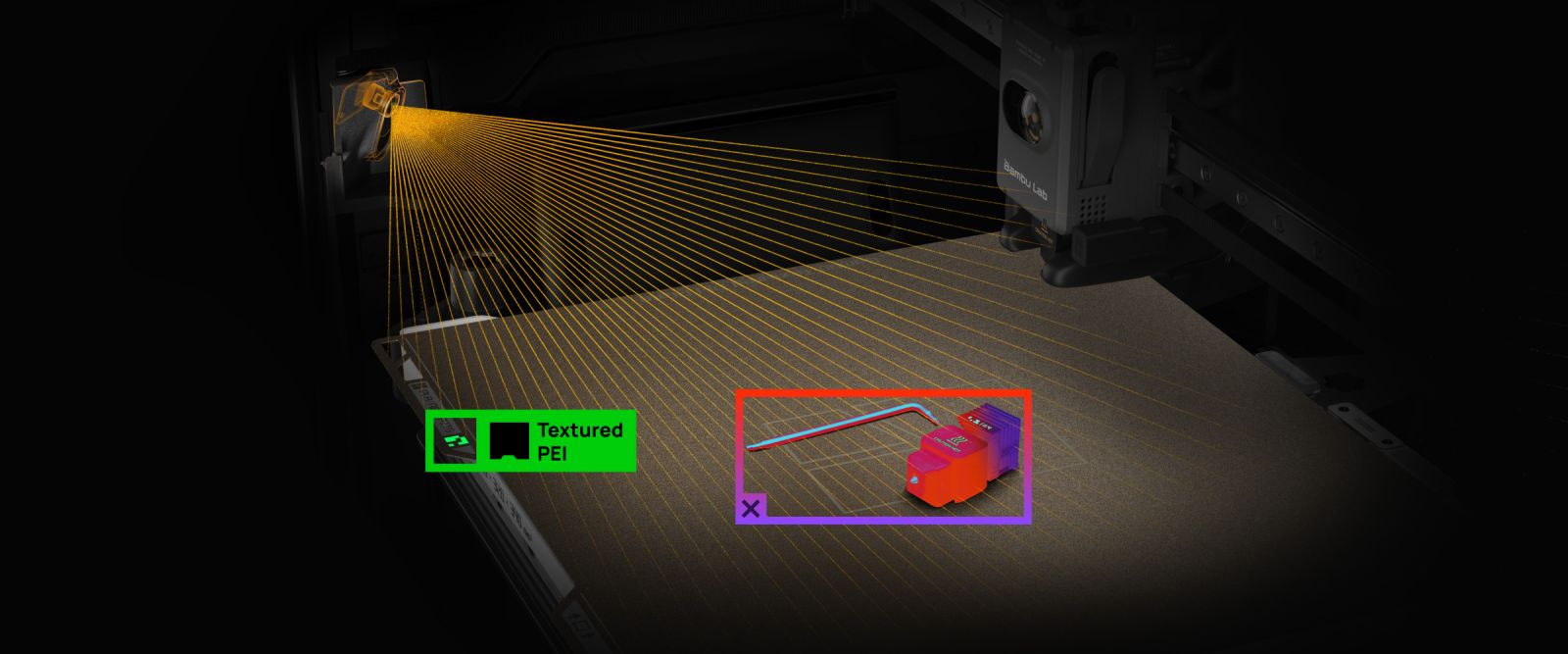

AI-Powered Vision SystemThe H2S vision system uses AI-driven real-time monitoring to detect clumping, spaghetti, or purge chute jams as they occur—stopping failures before they escalate. Beyond reliability, it unlocks advanced capabilities like Live Spatial Alignment for precise laser and cutting calibration, and Vision Encoder technology for enhanced positional accuracy across every print. |

|

|

Intelligent Filament MonitoringFilament-path sensors work in unison to monitor feeding speed and position, detect filament tangles and grinding risks, track filament mileage and spool usage, and ensure tool readiness across the AMS, buffer, cutter, and feeding paths, making sure every tool is in place and every move is under control. |

Thermal Control SystemsFive NTC temperature sensors are strategically positioned across the nozzle, heatbed, and chamber to deliver precise thermal feedback. Working in tandem with integrated airflow sensors, the system continuously monitors and adjusts internal conditions in real time—stabilizing temperatures, optimizing circulation, and ensuring the ideal environment for every material and print. |

|

|

Comprehensive Safety SystemThe H2S is equipped with five flame sensors, front-door and top-cover sensors, and an emergency stop button to ensure maximum protection. This integrated system detects potential fire risks, verifies enclosure alignment, and provides instant shutdown capability—safeguarding both your projects and your workspace at all times. |

Pre-Flight Checklist by AI

Prior to each operational cycle, the H2S vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan – Detects debris across the entire print surface. Hardware Configuration Audit – Instantly identifies build plate properties.

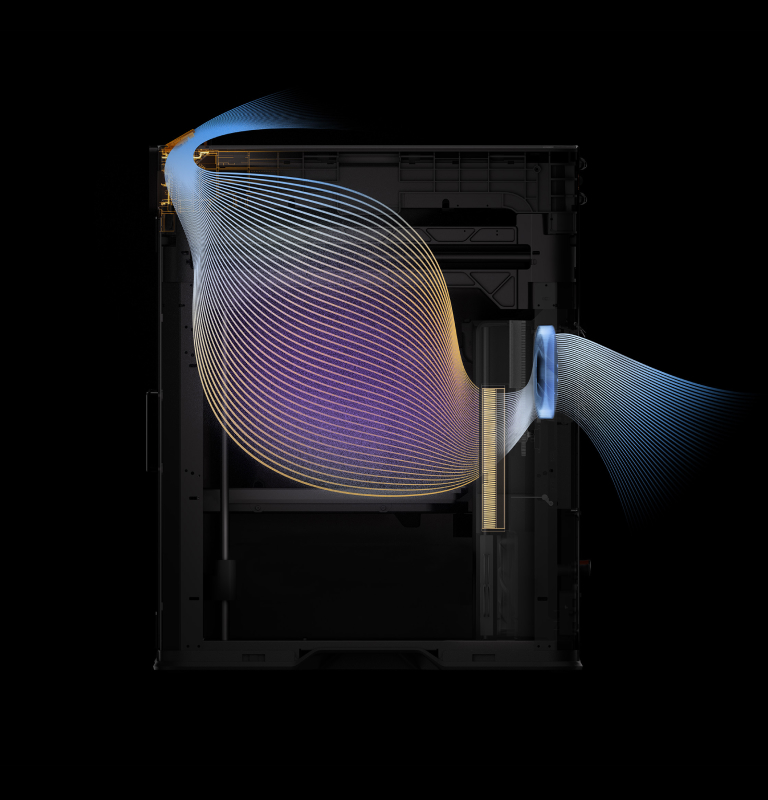

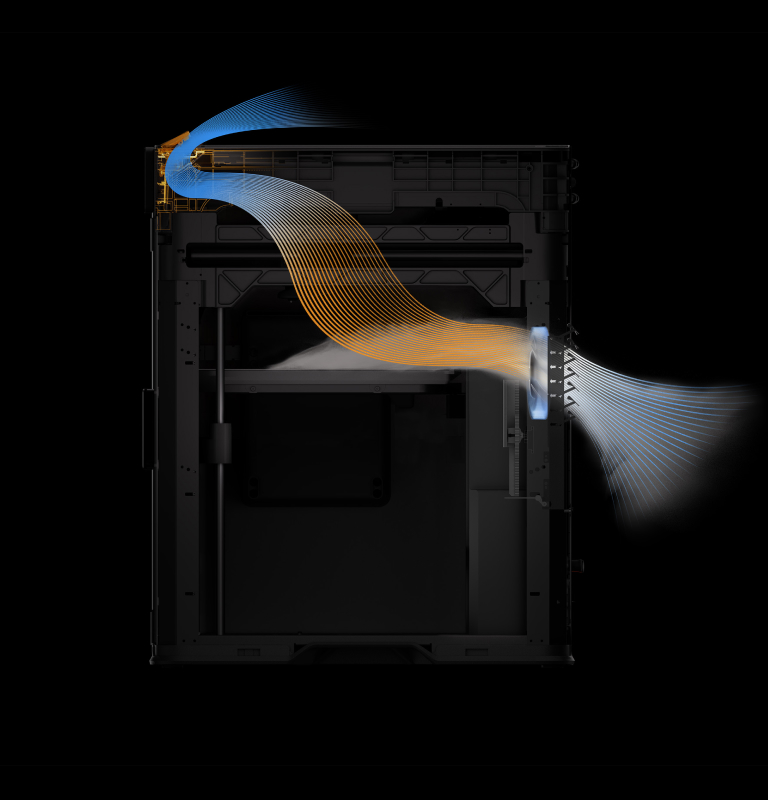

Flap Switch Airflow & Filtration System

|

Chamber sealed. Internal air recirculates through the Air Filter and the heater to stabilize high-temp conditions. Print large engineering parts without warping. |

Top Vent opens to bring in cool air, while maintaining a filtered exhaust. Print PLA and PETG without opening the door, and handle overhangs and bridging with ease. |

Top Vent and Filter Switch Flap open. Fumes are channeled efficiently to the ventilation system, keeping your workspace safe and clean. |

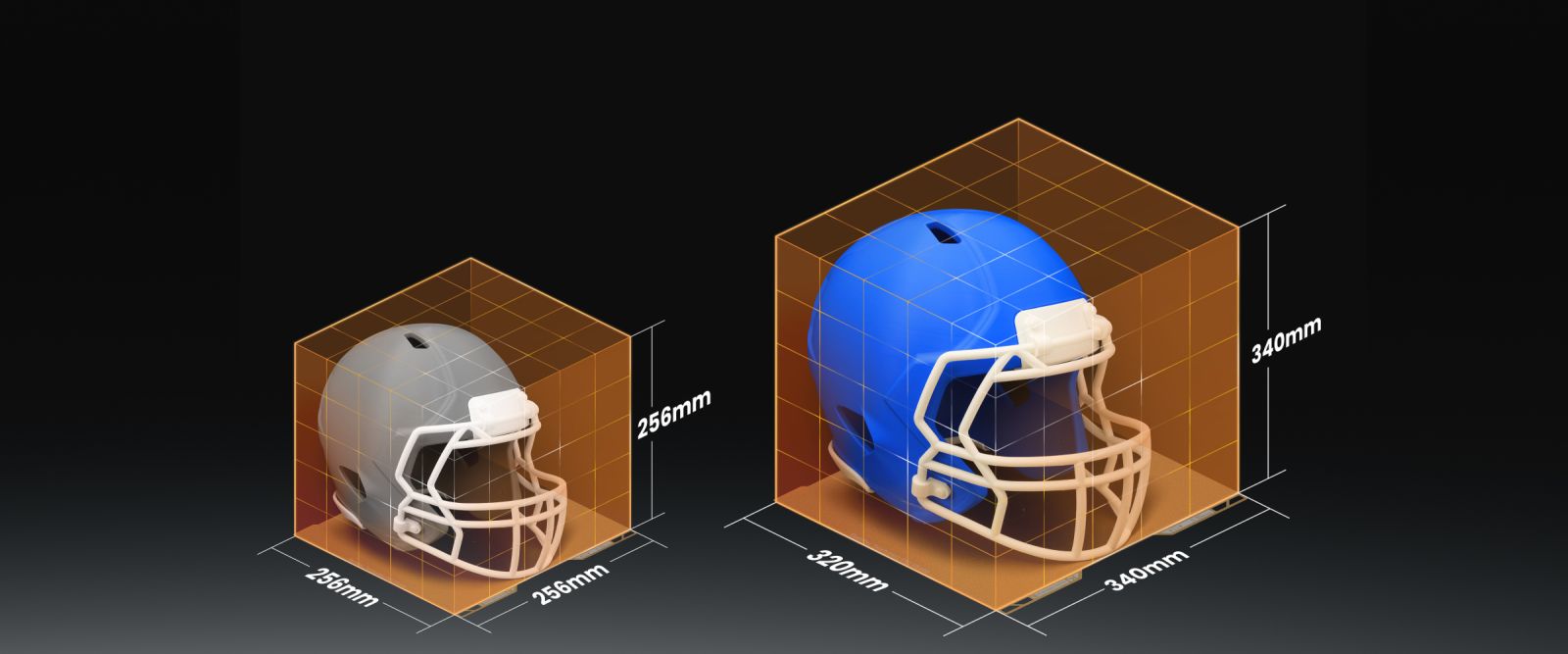

Bigger Faster Better

Maximum Volume. Maximum Productivity.

With a build volume of 340×320×340 mm³, the H2S offers the largest print space among all Bambu Lab printers. Your Vision. Fully Realized in One Print.

Top Speed. More Reliable Than Ever.

Bambu Lab’s proprietary PMSM servo extrusion system delivers 67% more extrusion force, ensuring stable support for high-flow printing. Combined with up to 1000 mm/s toolhead speed and 20,000 mm/s² acceleration, the H2S can run at full throttle cutting print times by up to 30% while still maintaining exceptional quality.

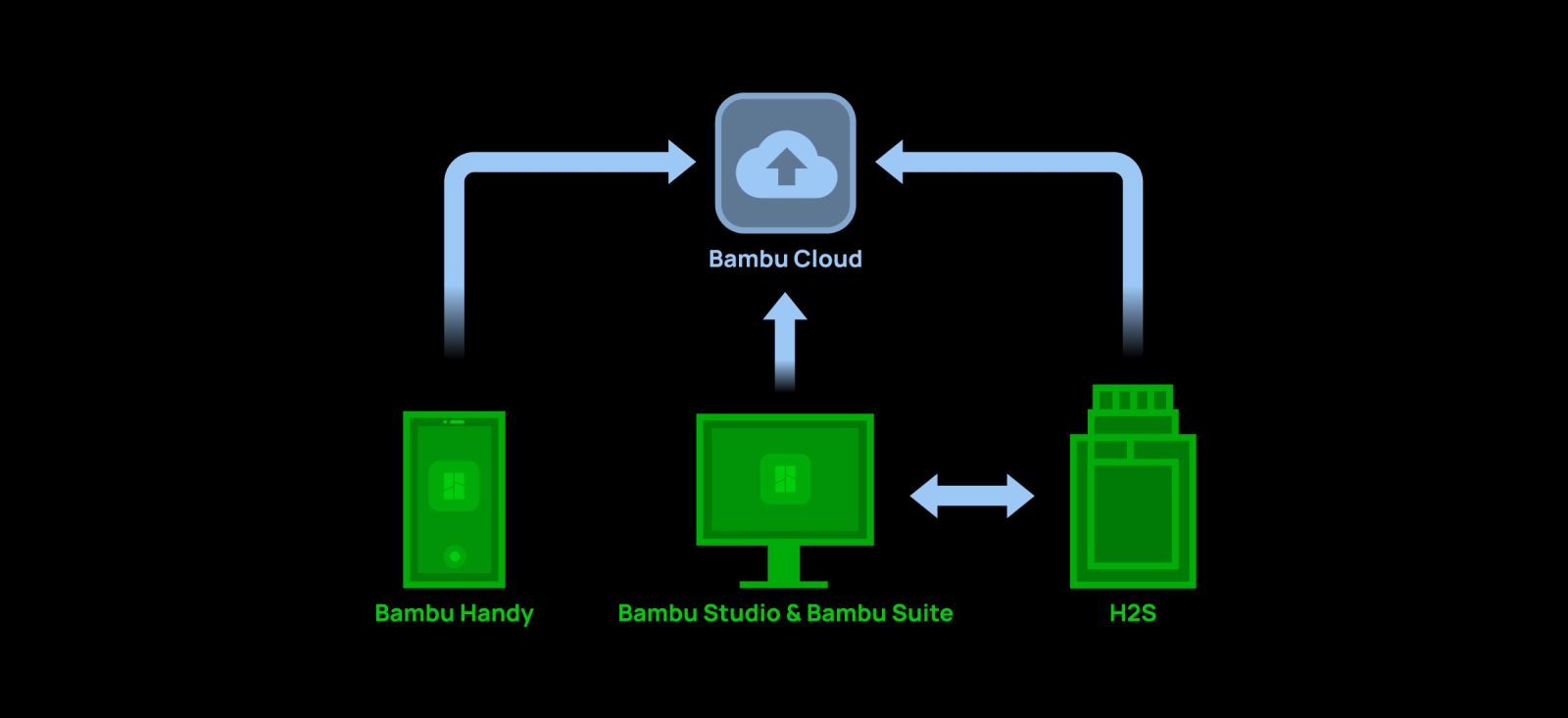

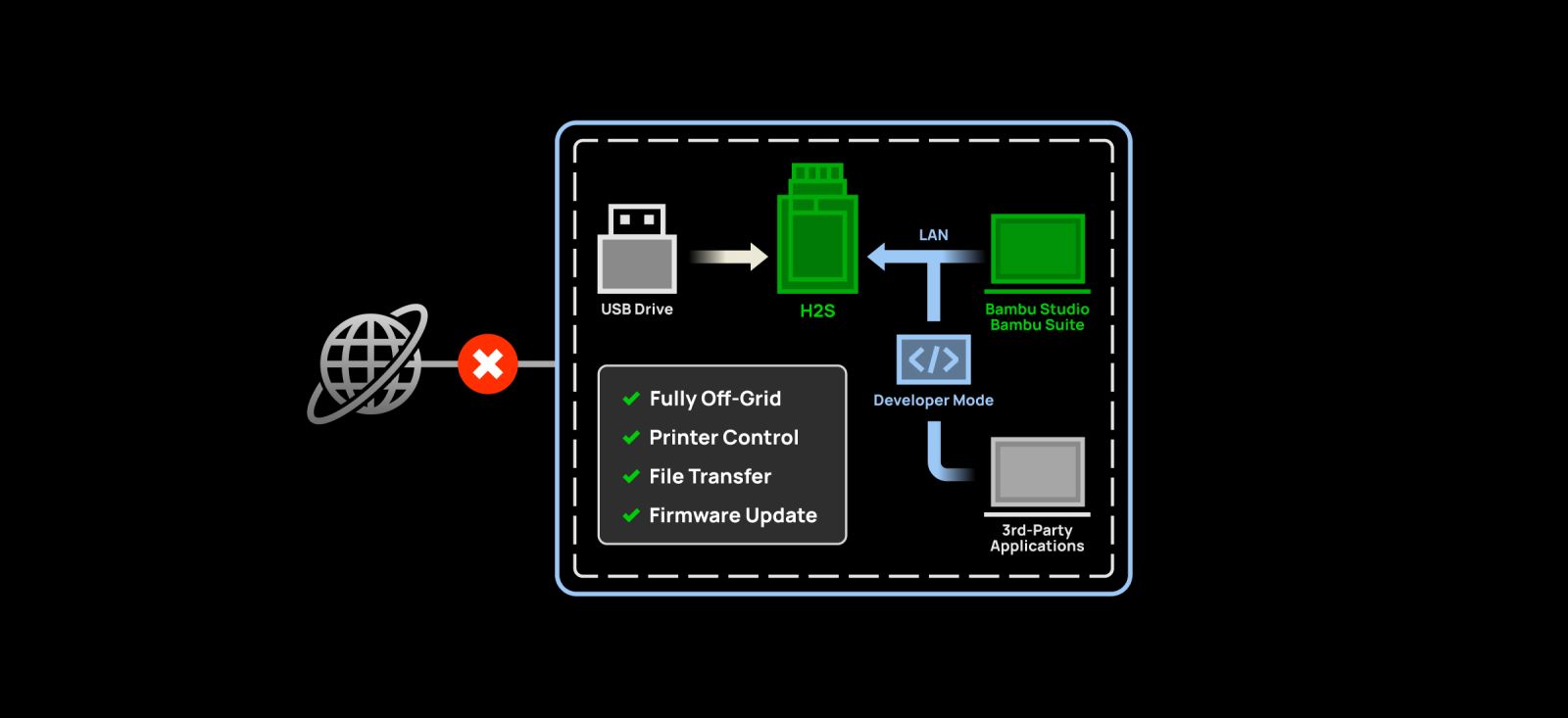

Connectivity, By All Means Privacy, By Design

The H2S offers seamless cloud connectivity for convenient remote control from any device. For security-sensitive applications, it also delivers complete offline functionality, ensuring physically isolated operation. Users can control the printer, send files, and upgrade firmware—no internet required. Additionally, Developer Mode unlocks MQTT port access, empowering developers and integrators to connect third-party components and custom software with ease.

Accessible. Comfortable. Made to Last.

Quick-Swap NozzleSwap nozzles in seconds, no tools, no hassle. Whether you're switching to a high flow hotend or a different nozzle size, the redesigned hotend makes it easy and intuitive, even for first-time users. |

|

|

Quiet by DesignWith Active Motor Noise Canceling and specialized air duct noise-reduction technology, the H2S operates below 50 dB. Print overnight or in shared spaces without disrupting your environment. |

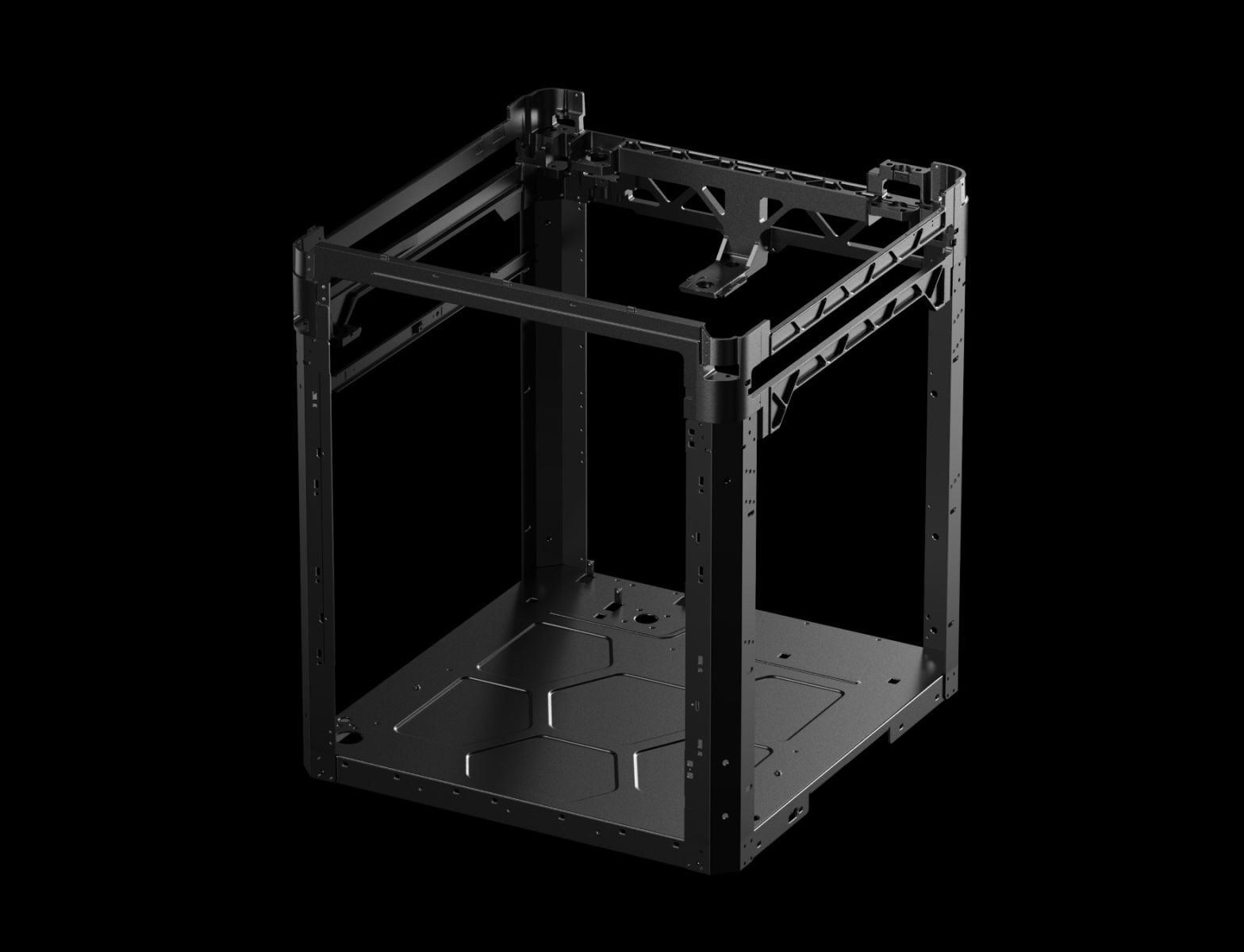

All-Metal, Die-Cast BodyThe integrated die-cast aluminum alloy chassis delivers a sturdy, stable structure that provides a rigid foundation for high-speed, large-format printing, while minimizing accuracy loss caused by micro-twisting. |

|

What's In The Box

.jpg)

Bambu Lab H2S |

Spool Holder |

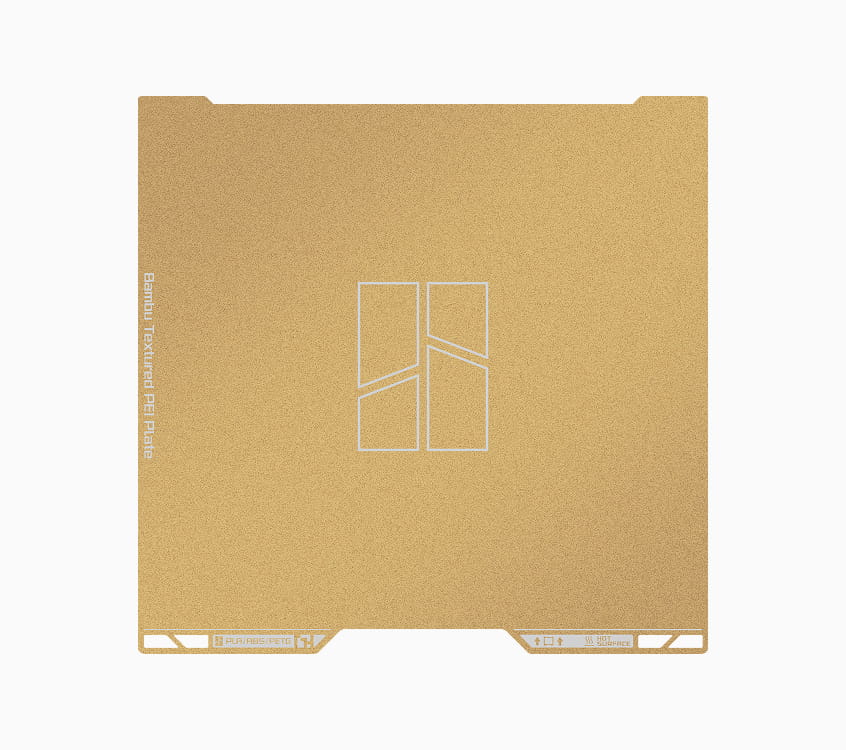

Textured PEI Build Plate |

Safety Key |

Accessory Box |

|

Bambu Lab H2S - Technical Specifications

| Printing Technology | |

| Technology | Fused Deposition Modeling |

| Body | |

| Build Volume (W×D×H) | 340×320×340 mm³ |

| Chassis | Aluminum and Steel |

| Outer Frame | Plastic and Glass |

| Physical Dimensions | |

| Physical Dimensions | 492×514×626 mm³ |

| Net Weight | 30 kg |

| Toolhead | |

| Extruder Gear | Hardened Steel |

| Nozzle | Hardened Steel |

| Max Nozzle Temperature | 350 ℃ |

| Included Nozzle Diameter | 0.4 mm |

| Supported Nozzle Diameters | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Filament Cutter | Built-in |

| Filament Diameter | 1.75 mm |

| Extruder Motor | Bambu Lab High-precision Permanent Magnet Synchronous Motor |

| Heatbed | |

| Build Plate Material | Flexible Steel Plate |

| Included Build Plate Type | Textured PEI Plate |

| Supported Build Plate Types | Textured PEI Plate, Smooth PEI Plate |

| Max Heatbed Temperature | 120 ℃ |

| Speed | |

| Max Speed of Toolhead | 1000 mm/s |

| Max Acceleration of Toolhead | 20,000 mm/s² |

| Max Flow for Hotend (Standard Flow) | 40 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 ℃ printing temperature) |

| Chamber Temperature Control | |

| Active Chamber Heating | Supported |

| Max Temperature | 65 ℃ |

| Air Purification | |

| Pre-filter Grade | G3 |

| HEPA Filter Grade | H12 |

| Activated Carbon Filter Type | Granulated Coconut Shell |

| VOC Filtration | Superior |

| Particulate Matter Filtration | Supported |

| Cooling | |

| Fans (Closed Loop Control) | Part Cooling Fan; Hotend Cooling Fan; Main Control Board Fan; Chamber Exhaust Fan; Chamber Heat Circulation Fan; Auxiliary Part Cooling Fan |

| Supported Filament Types | |

| Filament Supported | PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS; Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA, PPA, PPS |

| Sensors | |

| Live View Camera | Built-in; 1920×1080 |

| Toolhead Camera | Built-in; 1600×1200 |

| BirdsEye Camera¹ | Built-in; 3264×2448 |

| Door Sensor | Supported |

| Filament Sensors | Run-out, Tangle, Odometry (with AMS) |

| Power Loss Recovery | Supported |

| Electrical Requirements | |

| Voltage | 100–120 VAC / 200–240 VAC, 50/60 Hz |

| Max Power² | 2050 W @ 220 V / 1170 W @ 110 V |

| Working Temperature | |

| Operating Range | 10 ℃ – 30 ℃ |

| Electronics | |

| Touchscreen | 5-inch 720×1280 Touchscreen |

| Storage | Built-in 8 GB EMMC and USB Port |

| Control Interface | Touchscreen, Mobile App, PC App |

| Motion Controller | Dual-core Cortex-M4 and Single-core Cortex-M7 |

| Application Processor | Quad-core 1.5 GHz ARM A7 |

| Neural Processing Unit | 2 TOPS |

| Software | |

| Slicer | Bambu Studio. Supports third-party slicers that export standard G-code (e.g., SuperSlicer, PrusaSlicer, Cura), though certain advanced features may not be supported. |

| Supported Operating System | macOS, Windows, Linux |

| Network Control | |

| Ethernet | Not Available |

| Wireless Network | Wi-Fi |

| Network Kill Switch | Not Available |

| Removable Network Module | Not Available |

| 802.1X Network Access Control | Not Available |

| Wi-Fi | |

| Operating Frequency | 2412–2472 MHz (CE/FCC); 2400–2483.5 MHz (SRRC) 5150–5850 MHz |

| Transmitter Power (EIRP) | 2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC) 5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC) 5 GHz Band3: <30 dBm (CE); <24 dBm (FCC) 5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE) |

| Protocol | IEEE 802.11 a/b/g/n |

(64765)

| SKU | 64765 |

| Barcode # | 6937285505774 |

| Brand | Bambu Lab |

| Shipping Weight | 37.5000kg |

| Shipping Width | 0.620m |

| Shipping Height | 0.620m |

| Shipping Length | 0.755m |

| Shipping Cubic | 0.290222000m3 |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.

.png)