Bambu Lab P2S Combo 3D Printer

AMS 2 Pro Included

or 4 payments of $312.25 with

Info

Info

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

BAMBU LAB P2S Combo 3D PRINTER

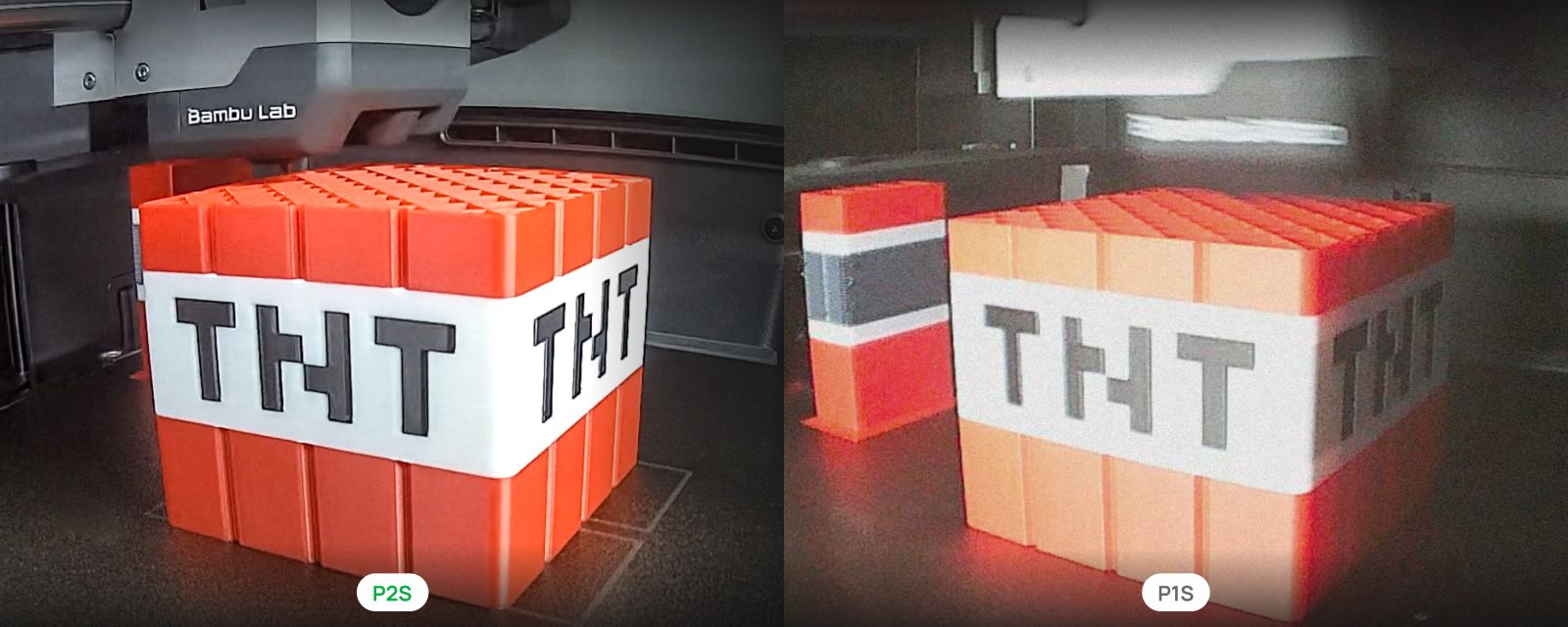

RELIABLE, MULTI-FILAMENT-READY PRODUCTION WITH SMART COOLING & AI

The Bambu Lab P2S brings the next evolution of the P-Series: a refined motion system, a hardened-steel extrusion path, and a new 5-inch touchscreen running the Gen-2 UI. Pair it with AMS 2 Pro (included in the P2S Combo, optional for P2S) to unlock multi-colour printing and active venting filament drying—all in a compact, enclosed platform that’s easy to run day in, day out.

Product Features

- 5-inch refreshed touchscreen with new Gen-2 UI for smoother, clearer operation.

- AI error/failure detection (spaghetti, nozzle clumping) powered by on-board NPU.

- Auto Flow Dynamics Calibration with eddy-current pressure sensing for consistently clean corners and walls.

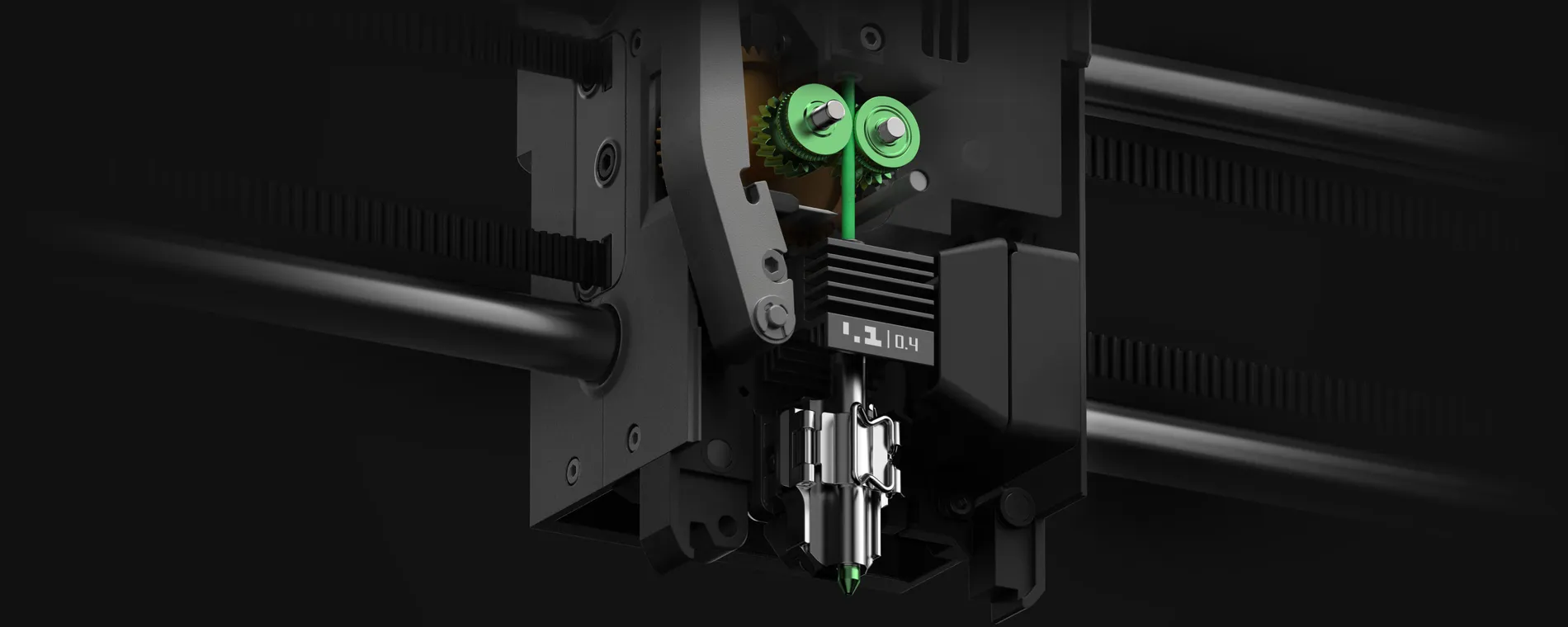

- Hardened-steel extruder gears + hardened-steel nozzle for long-term use with abrasive, fiber-reinforced filaments

- Adaptive Airflow System: cold-air intake for low-temp materials and heat-preservation mode for engineering filaments (up to ~50 °C chamber readiness).

- Quick-swap hotend with 1-clip nozzle change—about 30 seconds, no rewiring.

- 1080p live-view camera with enhanced lighting for crisp timelapses and remote monitoring.

- Activated-carbon air filtration with VOC/PM support to help keep your workspace cleaner.

- Compatible with AMS 2 Pro for multi-colour printing and active venting filament drying (included with P2S Combo; optional on P2S).

- 256 × 256 × 256 mm build volume in an enclosed chassis for dependable results.

Key Specs

- Max toolhead speed: 600 mm/s; max acceleration: 20,000 mm/s²; standard-flow max rate 40 mm³/s (tested with Bambu ABS).

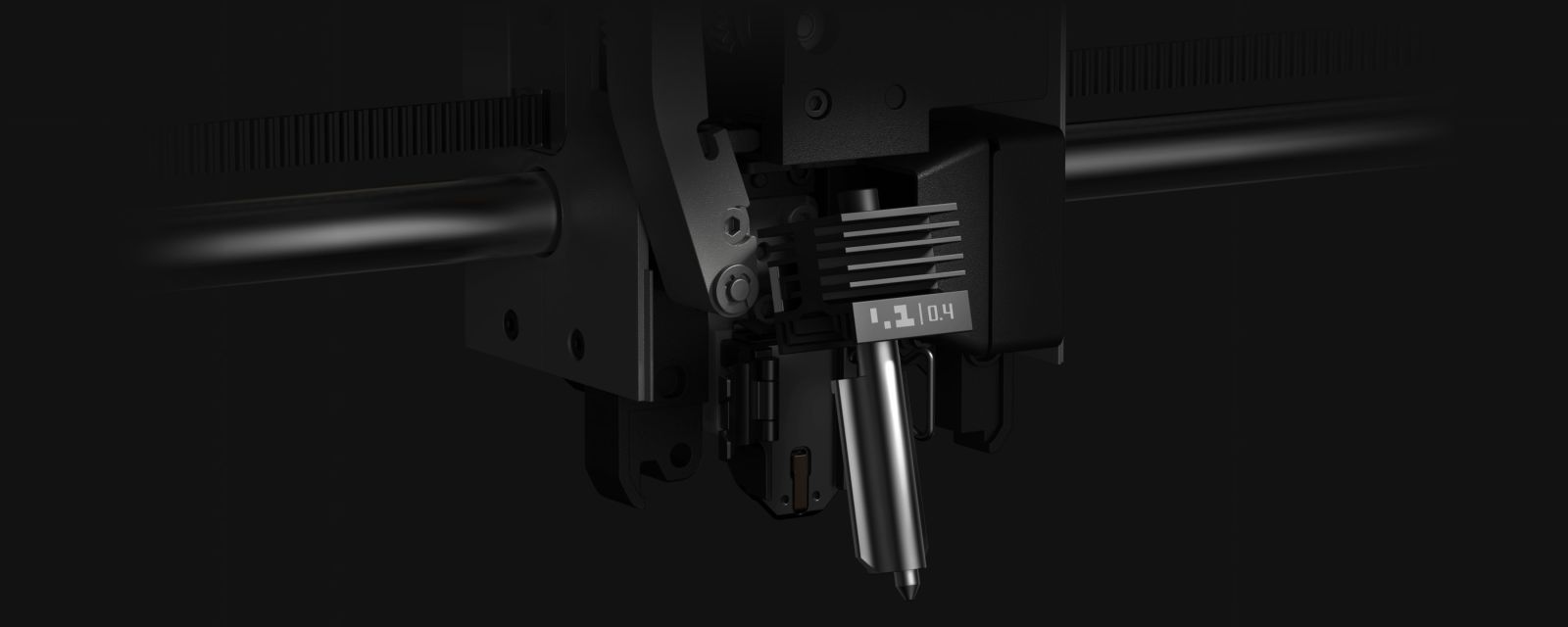

- Nozzle: 300 °C max; 0.4 mm installed; supports 0.2/0.4/0.6/0.8 mm

- Heatbed: up to 110 °C; flexible steel plates (Textured PEI included).

- Supported materials: PLA, PETG, ABS/ASA, TPU, PA/PC/PET blends, and fiber-reinforced (e.g., PA6-CF, PET-CF).

Notes: “P2S Combo” includes AMS 2 Pro and the 2-in-1 buffer; base “P2S” does not. P2S uses heat preservation via airflow control rather than an active chamber heater.

The Icon, Redefined

User Experience As Good As A Smartphone

The P2S gets a full interface refresh: a 5-inch touchscreen driven by a faster processor and Bambu’s new second-generation UI. Enjoy smoother gestures, sharper visuals, and clearer step-by-step guidance from setup to print finish.

5-inch Touch Screen | 2nd-Gen UI

.jpg)

70% More Extrusion Force & Real-Time Error Detection.

The P2S’s PMSM servo extruder delivers up to 8.5 kg of maximum extrusion force—70% more than its predecessor—dramatically improving high-flow stability. Our proprietary servo architecture samples resistance and position at 20 kHz, actively detecting filament grinding and clogs in real time.

PMSM Servo Architecture | DynaSense Extruder

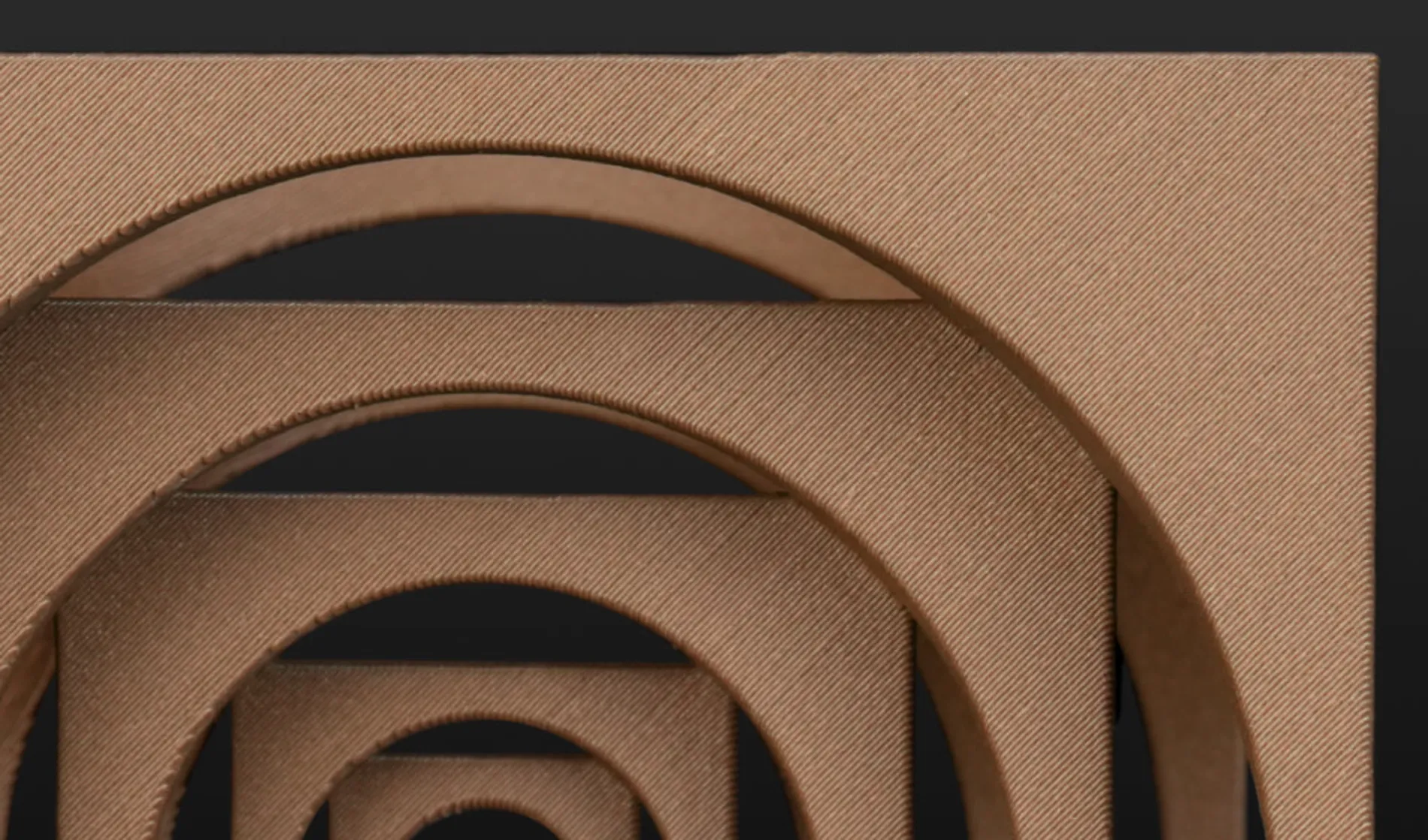

Print Smooth At Every Corner, Always.

The P2S uses a high-resolution, high-frequency eddy current sensor to calibrate flow dynamics. Intelligent algorithms actively adjust the flow rate based on these readings, providing precise, consistent extrusion across every layer and corner.

Active Flowrate Compensation | Eddy Current Pressure Sensor

Active Flowrate Compensation On |

|

|

Active Flowrate Compensation Off |

Adaptive Airflow System

Perfect Overhang No Matter the Filament or Temperature.

Unlike traditional cooling systems that recirculate hot air, the P2S’s Adaptive Airflow System draws in cool air directly from outside the chamber. This significantly improves cooling efficiency, letting you confidently print low-temperature filaments with the door closed—without worrying about overhang quality or nozzle clogs.

Cold-Air Intake | Cooling Mode

50°C Chamber Ready For Engineering-Grade Filaments.

The P2S features a flap-controlled Adaptive Airflow System that efficiently seals heat within the chamber while actively filtering the internal air through a high-performance carbon filter. This lets you confidently print demanding engineering filaments prone to warping, while maintaining clean, safe air quality in your workspace.

Heat Preservation | Carbon Filter

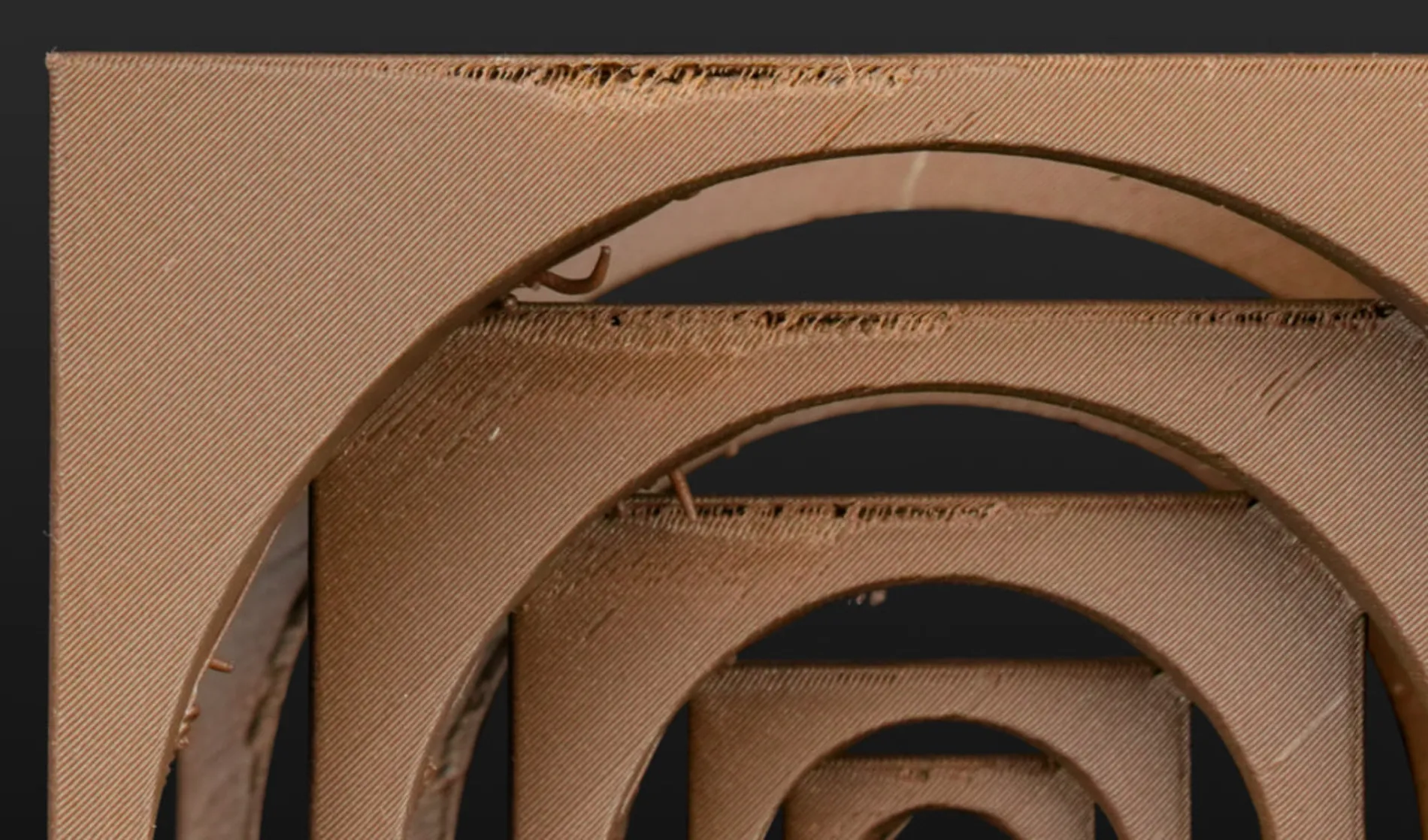

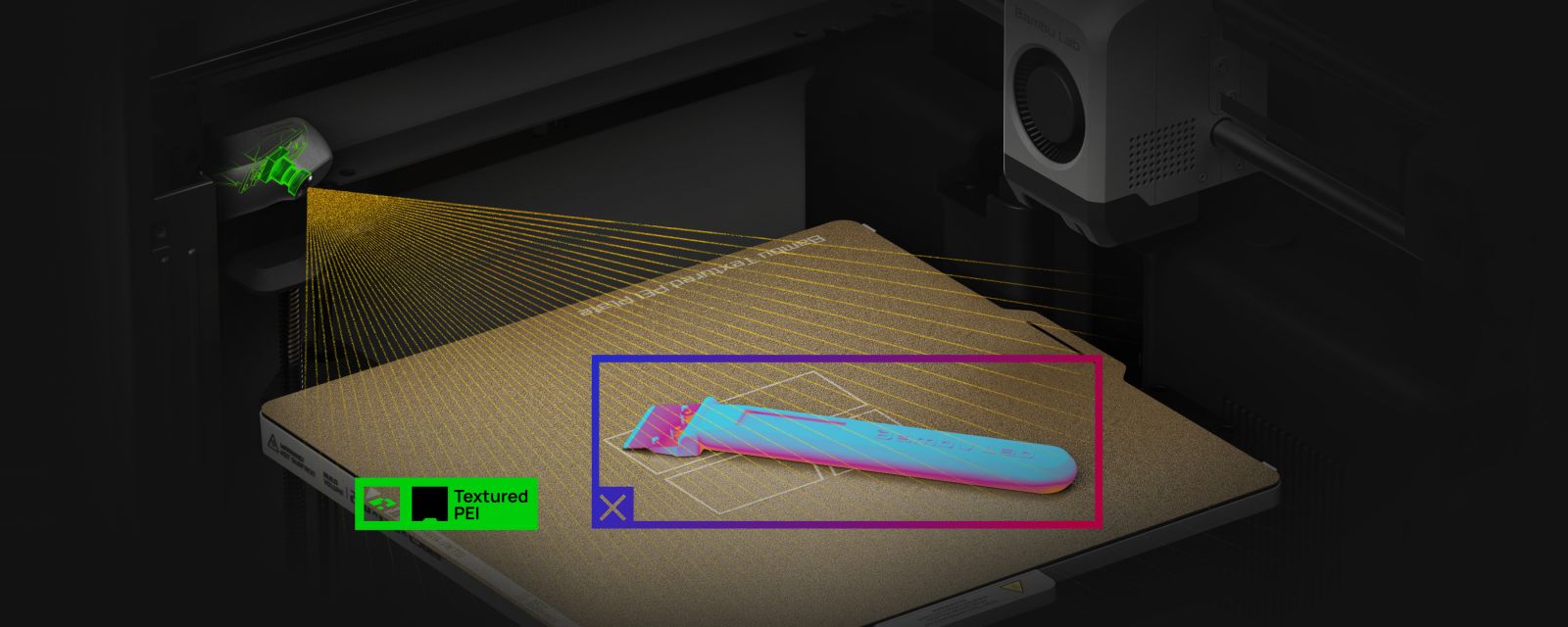

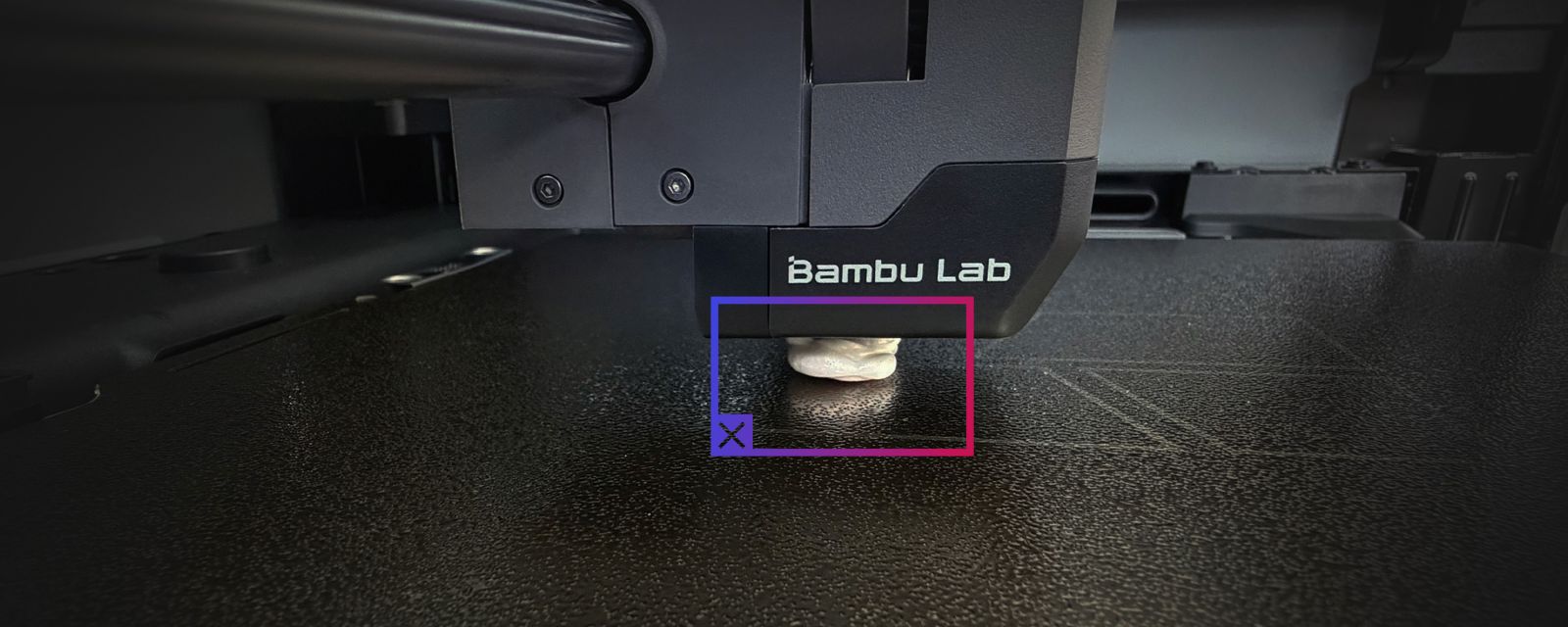

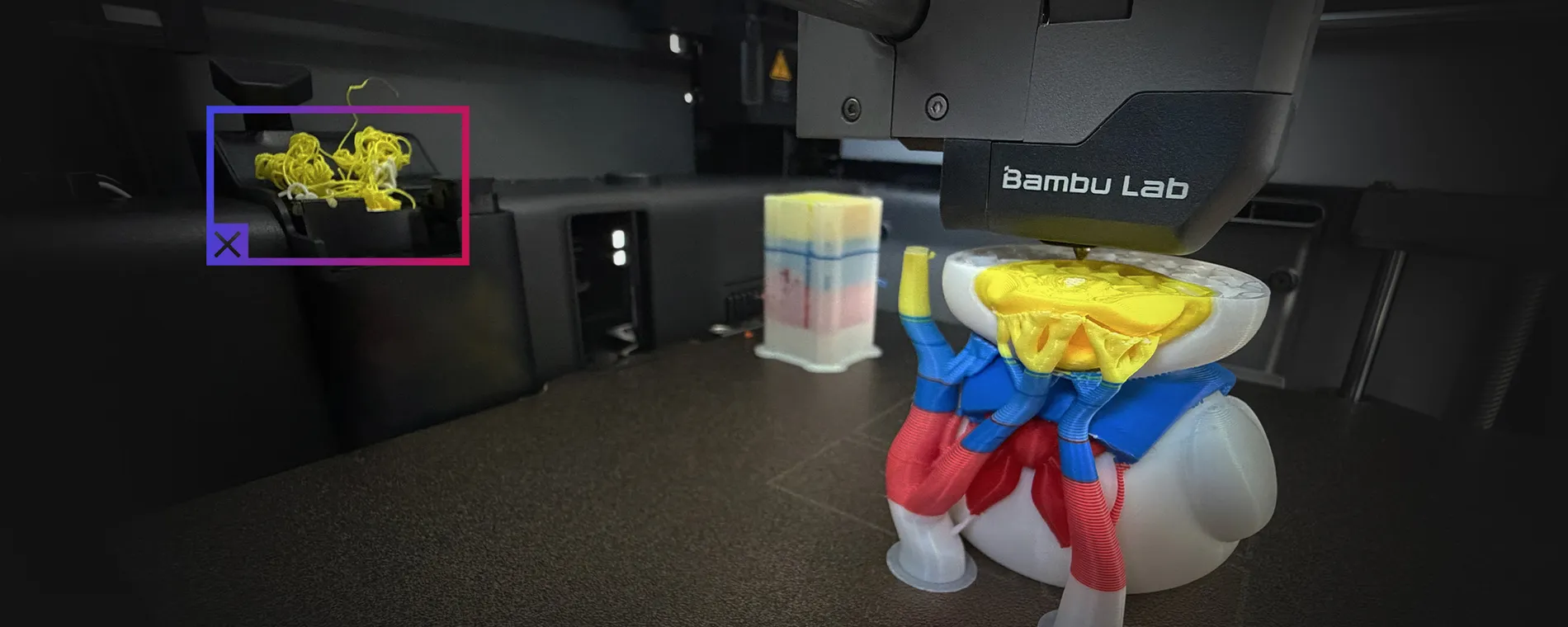

Peace of Mind, Every Time You Print.

The P2S introduces advanced AI computer vision that actively detects common issues like spaghetti and nozzle blobbing. It also runs smart start-of-print checks to help ensure a safe, accurate launch for every job—so you can hit print with confidence.

AI Error Detection | 2 TOPS NPU

Start CheckBefore every job, the P2S runs an AI-assisted Start Check: it verifies plate type and placement, confirms nozzle and bed temps, checks filament path/feeding, inspects the purge area, and validates first-layer readiness—helping each print launch cleanly and safely. |

|

|

Spaghetti DetectionComputer vision watches the part in real time and flags loose strands, off-bed extrusion, or layer detachments early. When detected, the printer can pause and alert you, reducing wasted time and material. |

Nozzle ClumpingThe AI monitors the nozzle area for blob formation and material build-up. If clumping is detected, the P2S can pause the job to prevent collisions or surface defects, helping maintain clean walls and reliable finishes. |

|

|

Purge Chute JamThe P2S checks the purge chute during filament changes and color swaps. If a blockage or buildup is detected, it can pause and prompt clearing to prevent misfeeds, failed tool changes, or stringing from incomplete purges. |

30-Second Nozzle Swap.

The P2S features a quick-swap hotend with a simple one-clip mechanism that releases the entire nozzle and heatsink assembly—no wiring disconnects required. Change nozzles in seconds while avoiding wiring mistakes and downtime.

Quick-Swap Hotend | 1-Clip Design

No-Lag Live View & High-Quality Timelapse.

Enhanced LED “stage” lighting dramatically improves the clarity of live view and timelapses. Combined with a high-frame-rate 1080p camera and dual-band Wi-Fi, you can monitor remotely with confidence and capture share-worthy, well-lit timelapses.

“Stage” Lighting | 1080p High-Rate Camera

Reliable for Fiber-Reinforced Materials.

The P2S extrusion path and nozzle use hardened steel for exceptional wear resistance, delivering stable, long-term performance with abrasive, fiber-reinforced filaments.

Hardened Steel Nozzle | Hardened Steel Extruder Gear

Perfection, Detail by Detail.

The P2S features numerous refinements that elevate the user experience. These incremental improvements may not be immediately obvious, but they reflect the relentless pursuit of perfection that defines Bambu Lab.

Built-in 2-in-1 Buffer (equipped with AMS combo)Effortlessly switch between your AMS and external filament spools for maximum flexibility. . |

.jpg) |

.jpg) |

Flat Base PlateThe smooth, flat surface makes it simple to swipe out all residue, keeping your printer clean. |

Integrated Lift HandlesDesigned for safe and easy transport, these sturdy handles protect your hands and provide a secure grip when moving the printer. |

.jpg) |

|

|

Shatter-Safe Front GlassEngineered for safety, the front glass is protected by a film built in case of shattering, protecting you and your workspace |

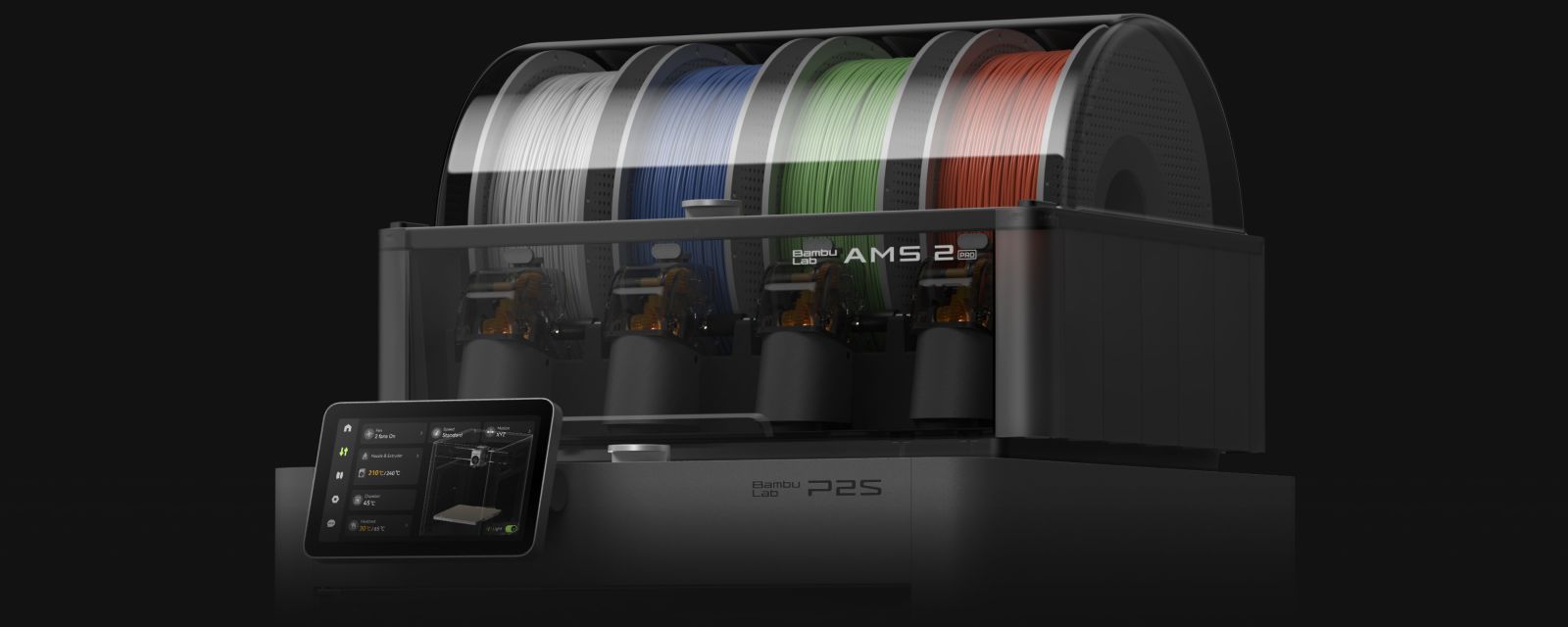

AMS 2 Pro - Multi-Colour Printing & Filament Drying, All in One Box.

Experience our most reliable multi-colour system yet. AMS 2 Pro adds long-awaited filament drying with a pioneering active-venting design that dries filament up to 30% faster than sealed heating, keeping humidity low for better storage and print quality.

Electromagnetic Air Vent

An automated electromagnetic vent opens for rapid dehumidification during drying, then seals airtight to preserve filament for weeks of consistent, high-quality prints.

Faster Multi-Colour Printing

A PMSM feeding motor speeds filament swaps by 60%, saving roughly 10 minutes for every 100 colour changes—less waiting, more making.

|

|

|

|

What's In The Box

Bambu Lab P2S |

Bambu Lab AMS 2 Pro |

Textured PEI Build Plate |

Spool Holder |

.jpg)

Accessory Box |

|

Bambu Lab P2S Technical Specifications

| Printing Technology | |

| Technology | Fused Deposition Modeling |

| Body | |

| Build Volume (W×D×H) | 256 × 256 × 256 mm³ |

| Chassis | Plastic and Steel |

| Outer Frame | Plastic and Glass |

| Physical Dimensions | |

| Physical Dimensions | 392 × 406 × 478 mm³ |

| Net Weight | 14.9 kg |

| Toolhead | |

| Extruder Gear | Hardened Steel |

| Nozzle | Hardened Steel |

| Max Nozzle Temperature | 300 ℃ |

| Included Nozzle Diameter | 0.4 mm |

| Supported Nozzle Diameters | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Filament Cutter | Built-in |

| Filament Diameter | 1.75 mm |

| Extruder Motor | Bambu Lab High-precision Permanent Magnet Synchronous Motor |

| Heatbed | |

| Build Plate Material | Flexible Steel Plate |

| Included Build Plate Type | Textured PEI Plate |

| Supported Build Plate Types | Textured PEI Plate, Smooth PEI Plate, Cool Plate SuperTack |

| Max Heatbed Temperature | 110 ℃ |

| Speed | |

| Max Speed of Toolhead | 600 mm/s |

| Max Acceleration of Toolhead | 20,000 mm/s² |

| Max Flow for Hotend (Standard Flow) | 40 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 ℃ printing temperature) |

| Filtration | |

| Filter Type | Activated Carbon |

| VOC Filtration | Supported |

| Particulate Matter Filtration | Supported |

| Cooling | |

| Part Cooling Fan | Closed Loop Control |

| Cooling Fan for Hotend | Closed Loop Control |

| Auxiliary Part Cooling Fan | Closed Loop Control |

| Supported Filament Types | |

| Filament Supported | PLA, PETG, ABS, ASA, TPU, Support for PLA, Support for PLA/PETG, Support for ABS, PET, PA, PC, PVA, PLA-CF, PETG-CF, ABS-GF, ASA-CF, PA6-CF, PA6-GF, PAHT-CF, PPA-CF, PET-CF |

| Sensor | |

| Camera | Built-in; 1920 × 1080; 30 fps HD |

| Door Sensor | Supported |

| Filament Run-Out Sensor | Supported |

| Filament Tangle Sensor | Supported |

| Filament Odometry | Supported with AMS |

| Power Loss Recovery | Supported |

| Electrical Requirements | |

| Voltage | 100–120 VAC / 200–240 VAC, 50/60 Hz |

| Max Power* | 1200 W @ 220 V / 1000 W @ 110 V |

| PLA Steady-State Power | 200 W @ 220 V / 200 W @ 110 V (PLA printing) |

| Working Temperature | |

| Operating Range | 10 ℃ – 30 ℃ |

| Electronics | |

| Touchscreen | 5-inch 854 × 480 Touchscreen |

| Storage | Built-in 8 GB EMMC and USB Port |

| Control Interface | Touchscreen, Mobile App, PC App |

| Motion Controller | Dual-core Cortex-M4 and Single-core Cortex-M7 |

| Application Processor | Quad-core 1.5 GHz ARM A7 |

| Neural Processing Unit | 2 TOPS |

| Software | |

| Slicer | Bambu Studio. Supports third-party slicers which export standard G-code (e.g., SuperSlicer, PrusaSlicer, Cura), but certain advanced features may not be supported. |

| Supported Operating System | MacOS, Windows, Linux |

| Network Control | |

| Ethernet | Not Available |

| Wireless Network | Dual-Band Wi-Fi |

| Network Kill Switch | Not Available |

| Removable Network Module | Not Available |

| 802.1X Network Access Control | Not Available |

| Wi-Fi | |

| Operating Frequency | 2412 – 2472 MHz, 5150 – 5850 MHz (FCC/CE) 2400 – 2483.5 MHz, 5150 – 5850 MHz (SRRC) |

| Wi-Fi Transmitter Power (EIRP) | 2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC) 5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC) 5 GHz Band3: <30 dBm (CE); <24 dBm (FCC) 5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE) |

| Wi-Fi Protocol | IEEE 802.11 a/b/g/n |

| * To ensure the heatbed quickly reaches the needed temperature (35–110 ℃), the printer will maintain maximum power for about 3–5 minutes. | |

(64585)

| SKU | 64585 |

| Barcode # | 6937285508447 |

| Brand | Bambu Lab |

| Shipping Weight | 21.4200kg |

| Shipping Width | 0.490m |

| Shipping Height | 0.490m |

| Shipping Length | 0.560m |

| Shipping Cubic | 0.134456000m3 |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.

.jpg)

.jpg)

.jpg) Filament Buffer

Filament Buffer