JS-FGF-800 Polymer Composite Printer

Build Size: 800 x 600 x 800mm

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

$10 Flat Rate Shipping - $10.00

- Delivery in 2-7 Business Days.

- Most Economical Option

- Australia Wide

- Online Tracking Available

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

JS-FGF-800 Industrial 3D Printer

Advanced Large Format Solutions from 3D Printer Gear

The Kings FGF-800 Pro, engineered with cutting-edge Fused Grain Structure (FGF) technology and innovative screw extrusion technology, represents a leap forward in industrial-grade 3D printing. Designed for both granular and polymer composite materials, this printer offers an unbeatable combination of affordability, speed, durability, and resistance to outdoor elements. With our proprietary consumables, enjoy rapid printing and forming speeds without compromising on strength or quality. Ideal for professionals seeking a large format 3D printer that delivers high performance with low material costs.

Features

.png)

Ideal Applications

The growing and diverse market demand has driven the use of large FGF 3D printers to solve a variety of complex issues including sculpture making, furniture design, toy industry, art crafts, mould manufacturing, landmarks, end-use products for the automotive, transport or marine industry etc.

-

Innovative Chair Design

Large-format granular 3D printing has revolutionized the design and manufacturing of chairs, offering unprecedented flexibility, customization, and efficiency. This technology has paved the way for designers and manufacturers to push the boundaries of creativity, functionality, and sustainability in chair design. Here's how large-format granular 3D printing has contributed to the creation of innovative and unique chair designs:

.png)

.png)

-

Short Lead Time Mould Manufacture

Traditional methods of manufacturing moulds from aluminium or steel typically require a lengthy cycle of 1 to 2 months. In contrast, large format FGF 3D printers dramatically reduce this timeframe to just 1 to 2 weeks. This accelerated process aligns mould production more closely with the pace of product design updates, significantly reducing the overall design and research & development period for businesses. Consequently, this method enhances workflow efficiency, particularly in the realm of creative projects, leading to faster realization of finished products. Large-format granular 3D printing plays a crucial role in this improved process by enabling the rapid production of moulds with complex geometries that would be time-consuming and expensive to create using traditional methods. This technological advancement not only speeds up production but also encourages innovation by allowing for more frequent iterations and updates in product design

.jpg)

-

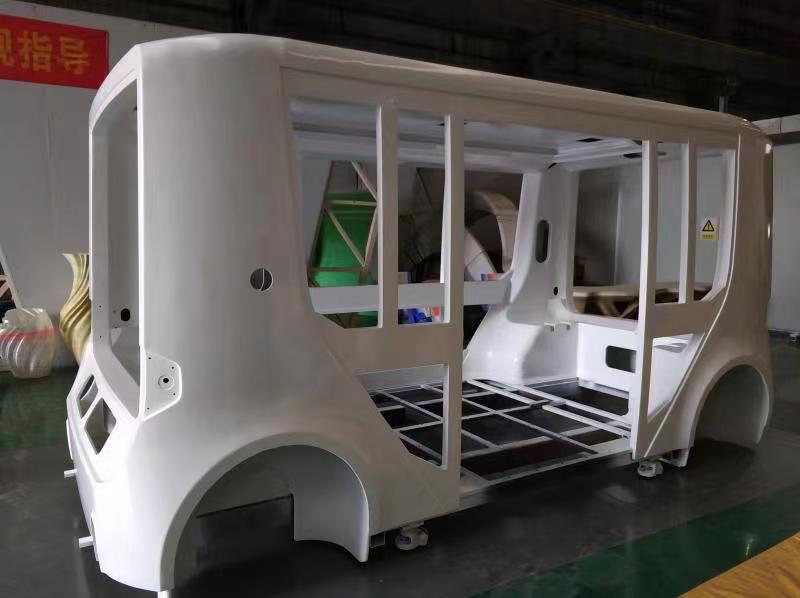

Large Format Automotive

Large-format 3D printing has revolutionised the automotive industry by significantly enhancing the speed and flexibility of the design and prototyping process. This technology allows for the rapid production of full-size automotive parts, drastically reducing the development timeline from concept to prototype. It enables the creation of complex and detailed components that were previously challenging or impossible to fabricate with traditional manufacturing techniques. As a result, automotive designers and engineers can iterate and optimise designs more quickly and efficiently, leading to innovations in vehicle performance, aesthetics, and functionality. The adoption of large-format 3D printing in the automotive sector underscores a shift towards more customisable, innovative, and efficiently produced vehicles, highlighting the technology's critical role in the future of automotive manufacturing.

-

Branding Elements

Large format 3D printing offers unparalleled advantages for branding and exhibits, serving as an invaluable tool for marketers, designers, and event organisers looking to craft impactful, memorable brand experiences. It enables unmatched customisation, allowing for the creation of bespoke branding elements and exhibit designs tailored to specific themes or corporate identities. This technology facilitates the production of large, intricate displays and signage that capture attention and communicate brand messages effectively. Moreover, large-format 3D printing supports the use of a wide range of materials, enabling the construction of durable, high-quality installations that can withstand the rigours of public display. Its cost-effectiveness and speed in producing large items make it ideal for meeting tight deadlines and budgets, while its sustainability aspect, through the use of eco-friendly materials, aligns with the growing demand for green marketing solutions.

Image Gallery

Below are examples of completed projects utilising the large build volume of the Kings FGF-800 3D Printer.

.png)

.png)

.png)

.png)

Technical Specifications

| General information | ||

|---|---|---|

| Printing technology | Fused Granular Fabrication | |

| Printing material | PLA/PETC/ABS/PC/PA/PP/HDPE/TPU/TPV/EVA PETG+GF/PPS+GF/PA+CF/ABS+CF/PC+CF/PEI+CF etc | |

| Build Dimensions | 800 x 600 x 800mm | |

| Printer Dimensions | 1130 x 1030 x 1632mm | |

| Nozzle Diameter Availability | 0.4mm - 3mm | |

| Weight | 200kg | |

| Nozzle Temperature | 350 Degrees Celcius |

| Nozzle Heating Method | Dual Zone Intelligent Screw Extrusion |

| Compressed Air Pressure | 0.6 MPa |

| Material Particle Diameter | 1-5mm |

| Storage Hopper Volume | 12kg |

| TAutomatic Feeder | Integrated |

| Power | |

|---|---|

| Power supply | 230 [V] AC, 50/60 [Hz], 7.5 [A] |

| Rated Power | 3 [kW] |

| Power Type | Single Phase |

(KINGS-JS-FGF-800)

| SKU | KINGS-JS-FGF-800 |

| Brand | Kings |

| Shipping Weight | 200.0000kg |

| Shipping Width | 1.100m |

| Shipping Height | 1.030m |

| Shipping Length | 1.632m |

| Shipping Cubic | 1.849056000m3 |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.