Kings P440

440mm*440mm*450mm

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

$10 Flat Rate Shipping - $10.00

- Delivery in 2-7 Business Days.

- Most Economical Option

- Australia Wide

- Online Tracking Available

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

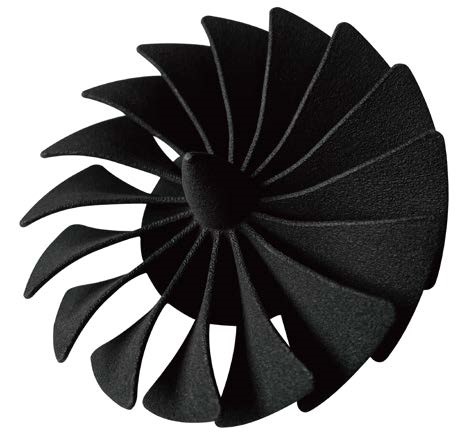

Kings P440 SLS Industrial 3D Printer

Advanced Large Format Solutions from 3D Printer Gear

In SLS printing, a high-powered laser selectively melts and fuses powdered material (usually nylon) layer by layer according to a 3D digital model. This process enables the creation of complex and intricate plastic parts directly from digital designs.

The process begins with a thin layer of plastic powder spread over a build platform. Then, a laser beam scans the powdered layer, melting and fusing the particles together according to the cross-sectional shape of the desired object. Once a layer is completed, the build platform descends by the thickness of one layer, and the process repeats until the entire object is fabricated.

SLS printing offers several advantages, including the ability to produce highly complex geometries, rapid prototyping, and the manufacture of parts with high strength and durability. It's commonly used in industries such as aerospace, automotive, medical, and engineering for producing components with specific material properties and intricate designs.

Features

- The original revival technology of PA powder makes the powder

utilization rate close to 100%, ensuring the high surface quality

and great mechanical properties of the parts. - Through the optimization of the anti-oxidation of consumables,

after the printing is completed, the cylinder can be taken to cool

down, and at the same time, the printing operation of the next

cylinder can be continued when the equipment is still at a high

temperature, which can effectively reduce the cooling and warm-up

time and reduce energy consumption. - Adopts an external powder cylinder to realize automatic powder

feeding and powder replenishment at any time during printing. - The scraper can be easily adjusted in multiple axes. Two-way

powder supply and powder spreading with double scrapers even

the powder spreading, improves the stability of the temperature

field and reduce the amount of powder spilled.

Ideal Applications

SLM printers can create models that are impossible to manufacture with standard manufacturing techniques. Models can be hollow or built with internal channels and components integrated into the design. SLM printing is commonly used in aerospace for reducing part counts and increasing reliability by creating a single part with coolant channels ducting and electrical components all integrated into one part.

-

Functional Prototyping

Selective Laser Sintering (SLS) is highly advantageous for both functional prototyping and the fabrication of complex geometries. In functional prototyping, SLS offers the ability to create parts with high strength and durability, making it ideal for testing prototypes that need to withstand mechanical stress or have specific material properties. This is particularly valuable in industries such as aerospace and automotive, where functional testing is critical. Simultaneously, SLS excels in producing complex geometries with intricate internal structures. Its layer-by-layer additive manufacturing process enables the creation of parts with intricate details, such as lattice structures or nested components, without the need for support structures. This capability unlocks new design possibilities and allows for the fabrication of parts that would be challenging or impossible to produce with traditional manufacturing methods. Therefore, SLS is a preferred choice for applications that demand both functional performance and complex geometries, offering versatility and efficiency in the production of innovative components.

.jpg)

.jpg)

-

Batch Production

Cost-Effectiveness: SLS is highly cost-effective for batch production of parts, especially when compared to traditional manufacturing methods like injection molding. Many parts can be printed in one build volume allowing for hundreds of prints to be made.

No Tooling Required: Unlike traditional manufacturing methods that often require expensive tooling, SLS does not require any tooling or molds. This eliminates the need for upfront investments in tooling, which can be particularly advantageous for small-batch production runs where the cost of tooling may not be justifiable.

Design Flexibility: SLS offers unparalleled design freedom, allowing for the production of highly complex geometries and intricate details without the need for additional tooling or assembly. This means that each part in a batch can be customized or optimized for its specific function, enabling the production of highly tailored components.

Fast Turnaround Times: SLS has relatively fast turnaround times compared to traditional manufacturing methods, especially for small to medium-sized batches. Once the 3D model is prepared, multiple parts can be produced simultaneously in a single build cycle, reducing lead times and enabling rapid iteration and production.

.jpg)

.jpg)

Image Gallery

Below are examples of completed projects utilising SLM printers.

.jpg)

.jpg)

Technical Specifications

Optical System

| laser | 60W CO2laser |

| Spot size(mm) | >0.28 (Variable spot) |

| Wavelength(um) | 10.6 |

| Laser lifetime center(h) | >50000 |

| Laser output power range | 5%-100% |

Scanning System

| Scanning system | 3 axis dynamic focusing |

| Deflection Angle | +11° |

| Scanning speed(mm/s) | 6500 |

| Light on/off delay(us) | 300-500 |

| Signal type | analog signal |

| Max gain drift(ppm/ | 100 |

| Max position drift(urad/ K) | 30 |

| Follow time(ms) | <0.44 |

Maintenance parameters

| Power supply | 380V, 3~/N/PE, 50Hz peak 15Kw |

| Overall installation accuracy(mm) | PE 0.04 |

| Parallelism of the double edge of the scraper(mm) | PE 0,02 |

| Parallelism between scraper and construction platform(mm) | PE 0.05 |

| Build volume(mm) | 440 (L) * 440 (W) * 450 (H) |

| Machine dimensions(mm) | 1852 (L) * 1335 (W) * 2278 (H) |

| Weight(KG) | 1980 |

Powder Delivery

| Powder supply method | Top feeding and bi-directional recoating |

| Powder collection method | Falling powder cylinder |

| External cylinder volume(m³) | 0.37 |

Features

| Laser cooling mode | Water cooling. |

| Laser two switch | Separate control to prevent misoperation |

| Feeding mode | External powder supply cylinder, fully automatic feeding |

Control System

| Main control card | Self-developed full-function control card LANRUI V2 |

| Temperature control | 8 zone independent temperature zone control |

| Way of temperature control | Gold-plated twin tube heating, continuous temperature monitoring compensation |

| Molding precision | +0.15mm (L<100mm); +0.2%*L(mm) 100mm) |

| Z-axis repeated positioning precision(mm) | 0.01 |

| Layer thickness(mm) | 0.1-0.12 |

| Powder laying method | Bi-directional recoating |

| Forming bin environment | Fully sealed pressurized nitrogen charging to ensure the stability of the processing environment |

| Ambient temperature requirement | Ambient temperature 15 ~ 31 °C; Relative humidity >30%, and no condensation |

(KINGSP440)

| SKU | KINGSP440 |

| Brand | Kings |

| Shipping Weight | 1.0000kg |

| Shipping Width | 1.600m |

| Shipping Height | 2.278m |

| Shipping Length | 1.335m |

| Shipping Cubic | 4.865808000m3 |

| Unit Of Measure | each |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.