KS808-BK - Black Resin

SLA Resin

Reseller, Corporate or Goverment Buyer?

Government and Education

3DPrintergear has been supplying government organisations with 3D printers, services and support since 2012. As an approved government customer you will automatically be entitled to 30-day terms with an official purchase order.

If you would like to create an account, please contact us on 1300 334 327, or at admin@3dprintergear.com.au

Resellers

Want to become a reseller?

3DPrintergear offers special pricing to genuine resellers. Once your application is approved, your new buying prices will be shown on our website after you login. To apply for a resellers account please contact us at admin@3dprintergear.com.au

$10 Flat Rate Shipping - $10.00

- Delivery in 2-7 Business Days.

- Most Economical Option

- Australia Wide

- Online Tracking Available

Free Pick-Up From Store - FREE

- Photo ID Required For All Pickup Orders

- Free pick-up from '781 High St, Reservoir VIC 3073', during opening hours

- Call Us 1300 334 327 if Urgently Required

- Express Dispatch

- Australian Owned & Operated

- Money Back Guarantee

- Quality Assured Products

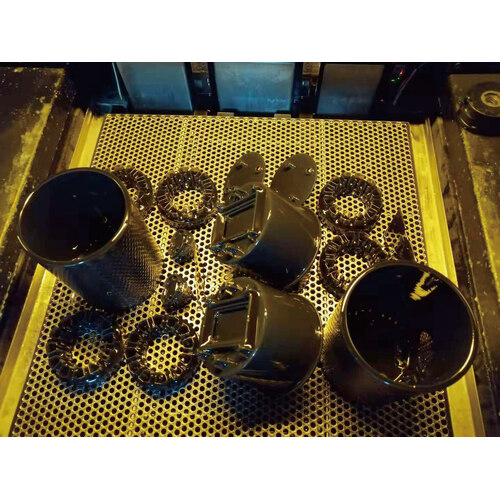

KS808-BK - Black Resin

Material Overview

KS808-BK ABS-like resin is a versatile charcoal black SL resin with high precision outstanding machinability and excellent durability. It provides long-term environmental stability with good impact strength, elongation, and tensile strength. This material is recommended for making conceptual models, master patterns, and functional parts in the shoe, automotive, medical, consumer electronics, etc industries.

Ideal Applications

Vacuum casting prototypes

Functional models need to be tough

Conceptual models

Low-volume production models

Shoe, automotive, medical, consumer electronics, etc applications

Advantages

Medium viscosity ensures easier re-coating and cleaning of parts and machines

Better strength and dimensional retention properties in wet environments

Long shelf life in the machine

Excellent surface quality, accuracy, repeatability

Need less part-finishing time, easier post-curing

The charcoal black color offers low shrink and good resistance to yellowing

Material Parameters

| Appearance | Charcoal black |

| Density | 1.12-1.14g/cm3 @ 25 °C |

| Viscosity | 350-505 cps @ 25 °C |

| Dp | 0.135-0.155 mm |

| 2 | |

| Ec | 9-12 mJ/cm |

| Building layer thickness | 0.05-0.12mm |

| MEASUREMENT | TEST METHOD | VALUE |

| 90-minute UV post-cure | ||

| Hardness,Shore D | ASTM D 2240 | 75-85 |

| Flexural modulus,Mpa | ASTM D 790 | 2,650-2,750 |

| Flexural strength,Mpa | ASTM D 790 | 60- 75 |

| Tensile modulus,Mpa | ASTM D 638 | 2,150-2,370 |

| Tensile strength,Mpa | ASTM D 638 | 25-30 |

| Elongation at break | ASTM D 638 | 12 -20% |

| Impact strength, notched lzod, J/m | ASTM D 256 | 48 - 60 |

| Heat deflection temperature, °C | ASTM D 648 @66PSI | 58-70 |

| Glass transition, Tg, °C | DMA,Epeak | 62-75 |

| Density, g/cm3 | 1.12-1.14 |

(KS808-BK)

| SKU | KS808-BK |

| Brand | Kings |

| Unit Of Measure | each |

Be The First To Review This Product!

Help other 3DPrintergear users shop smarter by writing reviews for products you have purchased.